Metal Core Heavy copper PCB

- To operate efficiently and ensure reliability, heat must be removed from heat-generating power components.

- As a result of faster speeds, reduced format, and more devices being populated on Printed Circuit Boards, more heat is being generated that must be removed for efficient operation.

- The move to sustainable energy increased the demand for energy management electronics which also create much heat because of the high electrical currents used on these applications (Power inverters for solar and wind energy, powertrain electronics for HEV)

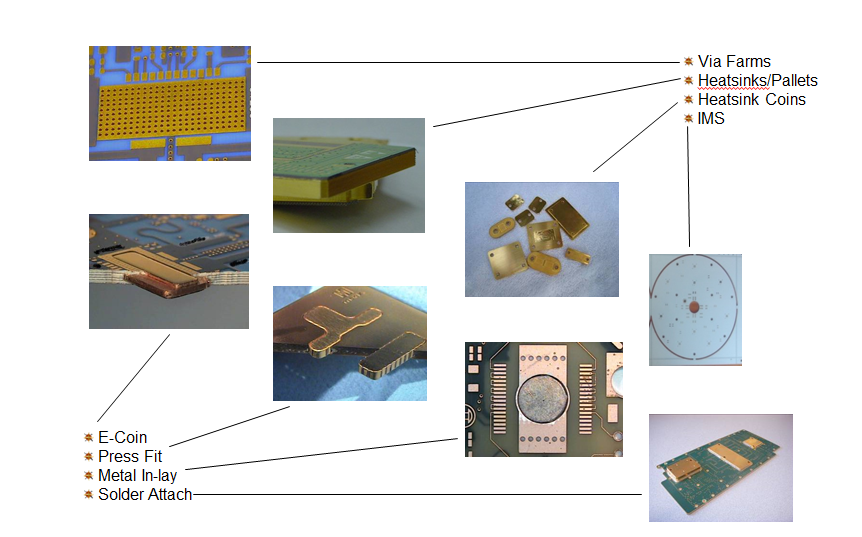

- Thermal management through various applications aids in directing heat away from heat-generating system components. The following is a review of various thermal management approaches, applications, and capabilities.

Applications requiring PCB Thermal management

It is important to utilize the best application for your thermal management application. Considerations of cost and how much thermal heat removal is required are important. Typical applications for Thermal Management may include:

- Power Applications: Power amplifiers, DC power supplies, Power control systems, RF/MW applications

- Automotive: Motor Control Modules, Electric brake system, Power-train in EV

- High-Speed Computing

- Lighting systems: Automotive, Industrial, Consumer

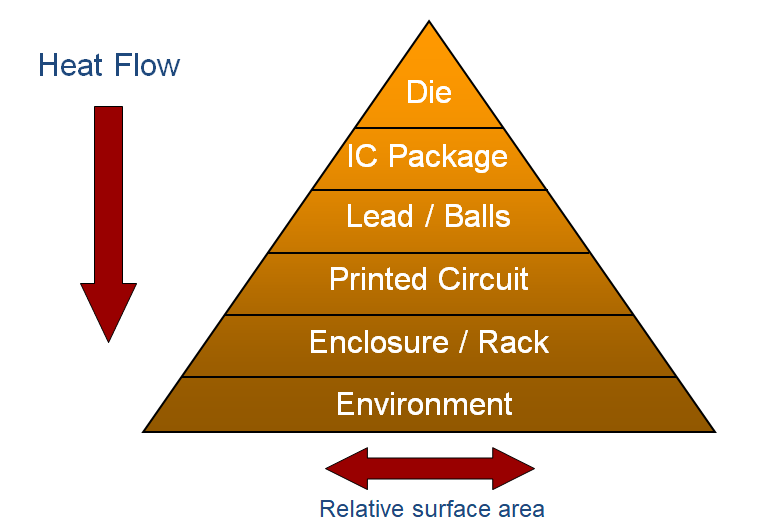

Thermal Conduction in PCBs

Thermal resistance at each level of an electronic system will impact conduction and Heat generated must be transferred to Environment.

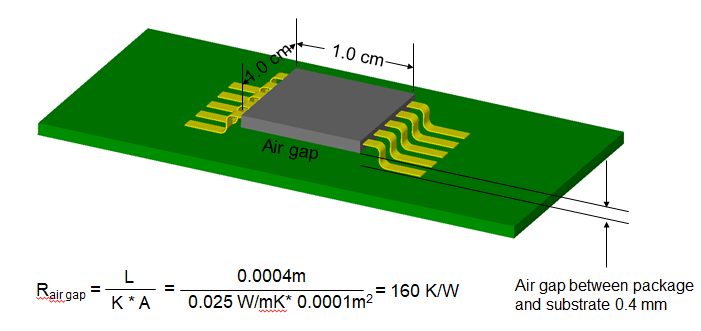

Air Gap Thermal Resistance

The air gap under components generally represents the greatest thermal resistance

- Air has a thermal conductivity of approximately 0.025 W/ mK

- Underfilling the component can dramatically reduce thermal resistance

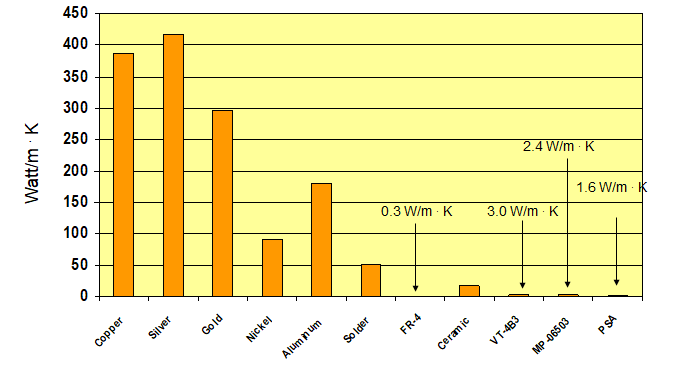

PCB Thermal Conductivities

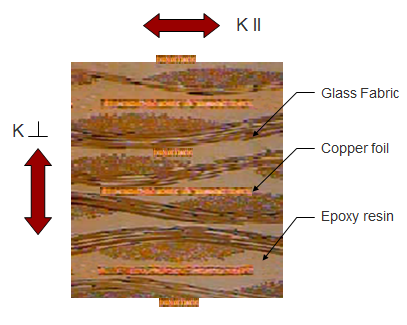

PCBs are composed of resin, glass, and a random distribution of copper that is parallel to the PCB surface. An approximate value for parallel and perpendicular conductivity is:

K II = 27.5 W/mK

K= 0.41 W/mK

Approximations are based on FR4-based laminate and will vary based on actual board construction and specific distribution of copper but they are a good starting point.

Thermal conductivities of common PCB materials

PCB Thermal Resistance: Parallel

This example does not take into account the thermal resistance from the IC and perpendicular resistance in the PCB

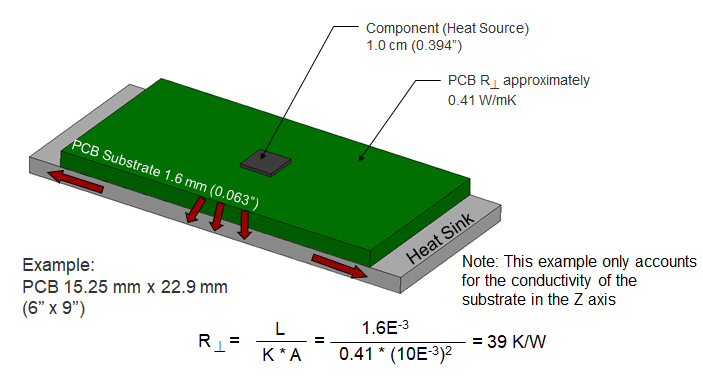

PCB Thermal Resistance: Perpendicular

Relatively large thermal resistance in the Z axis since copper layers are separated by high resistance laminate

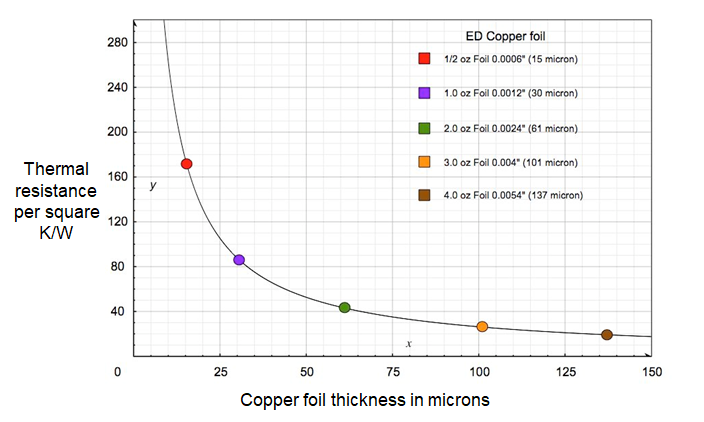

PCB Thermal Management – Heavy Copper

Thick Cu Outer layers in Printed Circuit Boards

External conductors, we can employ Copper-plate & Etch technology

210um (6Oz) final copper thickness on external layers

Heavy Copper Inner-layers in printed Circuit Board

6 Layer Heavy copper PCB

- Two cores with two 10oz/10oz copper layers based on the print and etch process

- To avoid reliability issues with extremely heavy copper on outer layers it is recommend to move heavy copper to inner layers

4 Layer Heavy copper PCB

- One core with two 410um (12 Oz) copper layers based on the print and etch process

PCB Thermal Management – Insulated Metal Substrate (IMS)

Insulated Metal Substrate (IMS) PCB Capabilities

| Al IMS (5052) | Cu IMS | |

| Material | Ventec Bergquist | Ventec Bergquist |

| Layer Count in MP | 1L | 1L |

| Max Panel size | 18” x 24” | 16” x 21” |

| Min dielectric layer thickness | 75um | 75um |

| Max Copper thickness | 3oz | 3oz |

| V-cut | Yes | Yes |

| Routing | Yes | Yes |

| Solder mask | Green, White, Black | Green, White, Black |

Insulated Metal Substrate PCB Case studies:

IMS PCB Example 1

Metal Type: 5052 Al

Dielectric thickness: 100um

Copper Thickness: 3 OZ

Al thickness: 1.9mm

Surface finish: LF-HASL

IMS PCB Example 2

Metal Type: 5052 Al

Dielectric thickness: 75um

Copper thickness: 2 OZ

Al thickness: 1.9mm

Surface finish: LF-HASL

IMS PCB Example 3

Metal Type: 5052 Al

Dielectric thickness: 75um

Copper Thickness: 3 OZ

Al thickness: 1.0 mm

Surface finish: LF-HASL

IMS PCB Example 4

Metal Type: 5052 Al

Dielectric thickness: 100um

Copper Thickness: 3 OZ

Al thickness: 1.0 mm

Surface finish: LF-HASL

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly, and box-build suppliers meeting your Required Electronic Manufacturing Capability, capacity, and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Systems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.