Understanding the importance of SMT reflow and wave soldering pallets

Surface Mount Technology (SMT) Reflow and wave soldering are the most fundamental steps in electronic assembly that are essential to making high-quality, reliable circuit boards. These processes require soldering fixtures, which are specialized tools with a crucial function in maintaining the integrity of solder joints as well as the overall effectiveness of the production process.

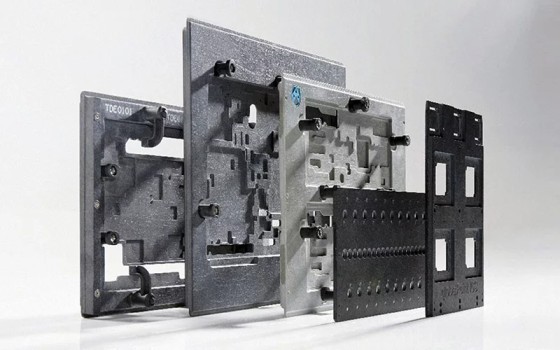

SMT reflow soldering entails the placement of surface mount components on a PCB, and heating the components with a precise method in order to melt solder paste creating secure electrical connections. Reflow soldering palettes, usually comprised of aluminum or specially designed composites, play a number of important functions within the process.

In the first place, pallets that reflow offer support and stability for the PCB throughout the heating process. This prevents the board from bending or warping that can result in misalignment of the parts and solder bridges. As long as they maintain the smoothness of the boards, they assure uniform solder joint construction across the entire assembly eliminating any defects and improving the overall quality of the product.

Reflow pallets also act as thermal barriers, redirecting heat to solder joints, while shielding sensitive components from extreme temperatures. This controlled heating aids in protecting components from damage or degrading which ensures the stability and durability of the electronic equipment.

When you use wave soldering, that is commonly used to make components with through holes the PCB is passed over the molten surface of solder creating solder joints between the lead of the component and the PCB pads. The pallets for wave soldering serve the same purposes as the reflow ones, but they are specifically made to resist the extreme conditions that come with a soldering wave.

These soldering palettes for Wave are made of materials with great thermal conductivity and superior resistance to flux and solder. They can withstand repeatedly being exposed to the molten flux without warping or deteriorating and ensuring consistent performance across several manufacturing cycles.

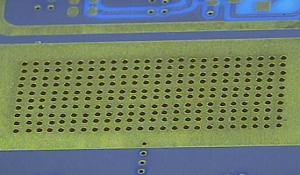

Furthermore, the wave soldering pallets come with precise designs to allow for the precise arrangement of the through-hole components on the PCB, which ensures an appropriate alignment and spacing to ensure solid solder joint construction. The attention to detail assists in eliminating any defects, such as solder bridges and faulty solder joints, thereby increasing the efficiency and yield of the process.

SMT reflows and wave soldering pallets are essential tools used in electronic assembly. They offer crucial support, thermal management, and precise alignment in the process of soldering. Through investing in top-quality pallets, and optimizing their designs to meet specific requirements for manufacturing electronic manufacturers can improve the efficiency, consistency, and quality of their manufacturing procedures, resulting in top-quality products for their clients.

What are SMT pallets for reflow?

SMT pallets for reflow are special equipment used for the surface mount technology (SMT) process of reflow soldering. They serve a variety of functions such as providing support, thermal control, and precise alignment throughout the process of soldering.

The materials used for SMT pallets to reflow

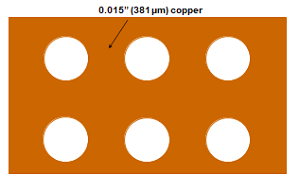

SMT reflow pallets are generally made of materials that have outstanding thermal conductivity, superior dimension stability, as well as the ability to withstand thermal shock and chemical exposure. The most common materials are stainless steel, aluminum, and special composites, including glass-reinforced epoxy laminate. The materials chosen are based on their capacity to endure the extreme temperatures and abrasive conditions encountered during the reflow soldering procedure but still maintain precise dimensions and evenness.

The design of SMT pallets to reflow

Many important design aspects must be considered when making designs for SMT pallets for reflow:

- Thermal Management: The pallet has to efficiently disperse heat throughout the process of reflow soldering and ensure that components and PCB meet the minimum soldering temperatures and reduce thermal stress on delicate components.

- Support and alignment: A pallet must provide sufficient support to the PCB in order to stop warping or distortion due to heating. It should also ensure an exact alignment of components that ensures uniform solder joint construction.

- Material compatibility: The material used for the pallet should be compatible with the solder paste and flux that are used for assembly making sure that it does not chemically react or infect those solder joints.

- Surface Finishing: The surface of the pallet needs to be flat and smooth in order for easy removal of flux from solder and to prevent solder bridges or other problems.

Benefits of SMT Reflow pallets

Reflow pallets provide a number of advantages for electronic assembly.

- Increased quality: Reflow pallets maintain a uniform joint of solder and avoid defects like solder bridges or inadequate solder, leading to better assembly with less defects.

- Improved Reliability: Through providing exact alignment and thermal control Reflow pallets can reduce the possibility of component damage or failure caused by excessive heat or soldering issues.

- More Efficiency: Reflow pallets simplify the assembly process, facilitating batch processing as well as reducing the hand-handling of PCBs leading to higher efficiency and lower costs for labor.

Solutions and common problems in the SMT reflow pallet design

The process of designing SMT pallets for reflow involves taking on many common issues, such as:

- Warpage: To stop stretching of the pallet or PCB when heating is taking place, components with a lower CTE (CTE) as well as the correct reinforcement are recommended.

- The buildup of flux residues is commonplace: Regularly cleaning and maintaining the pallet’s surface will stop the build-up of flux residue and ensure consistent soldering performance.

- Component Clearance: Making sure there is adequate clearance between components as well as the surface of the pallet prevents from causing damage or interference in the process of soldering.

When carefully analyzing these aspects in conjunction with the right design options manufacturing companies can improve the efficiency and durability of SMT pallets that reflow, which contribute to the overall performance of electronic assembly processes.

The explanation of how to solder pallets using wave technology

Pallets for soldering on waves are that are used in the electronic manufacturing sector to keep PCBs printed on circuit boards (PCBs) on their feet when the soldering process is carried out by a wave. This involves passing PCBs through a wave of liquid solder, which is used to join components to the board.

Types of Wave Soldering Pallets:

- Conventional Pallets: Conventional Pallets are the basic pallets that consist of fiberglass, composites, or aluminum. They offer a sturdy base to support PCBs when soldering in waves.

- Titanium Pallets: Titanium pallets provide high durability as well as resistance to the corrosive nature that is a hallmark of the molten solder. They’re ideal to be used for a long time, and they can endure repeated exposure to extreme temperatures.

- Modular pallets: They permit the flexibility of accommodating various PCB shapes and sizes. They comprise interchangeable modules which are adjustable to accommodate different board configurations.

Materials Selection for Wave Soldering Pallets:

- Material’s Heat Resistance: Material’s Heat Resistance must be able to endure the extremely high temperatures generated by the process of wave soldering without deforming or warping.

- Chemical Resistance: Materials for pallets have to resist corrosion due to the fluxes as well as molten solder. to ensure longevity and dependability.

- Material Thermal Conductivity: Material Thermal Conductivity having high thermal conductivity can distribute heat equally across the surface of the pallet to ensure an even soldering.

Design Principles for Effective Wave Soldering Pallets:

- Secure Fixture: Pallets are designed to securely fix PCBs to stop the board from moving or shifting during soldering.

- Affordable Support: Create pallets that provide adequate support for PCBs so that they are not the board from bending or stretching which could affect the soldering performance.

- Simple Loading and Unloading: Pallets will facilitate simple load and unloading of PCBs in order to make the manufacturing process more efficient.

- The minimum contact area: Limit the area of contact between the PCB and pallet to reduce solder bridging, and to ensure that the flow of solder is correct.

Benefits of Utilizing Wave Soldering Pallets:

- Better Soldering Quality: Pallets assure consistent PCB placement minimising the chance of problems such as solder bridges that are not properly soldered joints.

- Improved throughput: Efficacious pallet designs reduce the set-up time as well as increase the efficiency of the soldering process.

- Cost savings: Through decreasing defects and increasing the quality of the process, welding pallets could result in lower costs due to less the need for rework as well as scrap.

- Improved Durability: Top-quality pallet materials provide durability and durability, which reduces the requirement of frequent replacements for pallets.

- Modular pallet designs: Modular pallet designs enable an easy adaption to various PCB dimensions and configurations which increases the flexibility of manufacturing.

Key Differences Between SMT Reflow and Wave Soldering Pallets

Surface Mount Technology (SMT) Reflow and Wave Soldering are two of the most common methods used in electronic assembly. Each comes having its own unique specifications for pallets. The following are some of the major distinctions between the different pallets utilized for SMT Reflow and Wave soldering techniques:

- Material Compatibility:

- SMT Reflow Pallets are typically constructed from materials that are able to endure high temperatures like aluminum, ceramic and high-temperature plastics such as PEEK (Polyether Ether Ketone) or Ultem.

- Wave Soldering Pallets: Need to withstand exposure to molten solder, usually made from materials such as high-temperature-resistant plastics like PTFE (Polytetrafluoroethylene), fiberglass, or certain metal alloys.

- Thermal Properties:

- SMT Reflow Pallets: Created to effectively transfer heat throughout the reflow process, while ensuring dimensions stability, ensuring the exact positioning of components as well as solder joint creation.

- Wave Soldering Pallets must be able to withstand thermal shock, and keep stable at temperatures that are high, since they’re in the direct touch of molten solder.

- Design and Construction:

- SMT Reflow Pallets have intricate designs that are tailored to suit specific PCB layouts and heights of components. These may include details like grooves, holes or areas that are raised to aid in efficient thermal transfer and alignement.

- The Wave Soldering Pallets are of a more simple design and aim to provide enough support and security for parts during the process of welding. These may also include features such as gaps or slots to permit solder flow to the PCB’s bottom.

- Surface Coating:

- SMT Reflow Pallets may be coated or treated to increase thermal conductivity and prevent adhesion of solder or enhance release properties.

- Wave Soldering Pallets are often covered with materials that resist solder adhesion like Teflon or other special coatings to stop solder from sticking to the surface of the pallet.

- Cleaning Requirements:

- SMT Reflow Pallets require only minimal care since they do not come into close contact with solder. The majority of residues are cleaned with simple cleaners.

- Wave Soldering Pallets require a deeper cleaning in order to eliminate flux residues and solder splatters, particularly if they’re reused several times. The compatibility with cleaning procedures as well as chemicals is vital.

- Cost and Lifespan:

- SMT Reflow Pallets: Often more expensive due to the use of high-temperature-resistant materials and intricate designs. But, they may last longer provided they are maintained in a proper manner.

- Wave Soldering Pallets: generally cheaper, however their longevity may be reduced because of exposure to extreme soldering conditions that can cause degrading and wear over the course of time.

Best Practices for SMT Reflow and Wave Soldering Pallets

Surface Mount Technology (SMT) Wave and reflow soldering pallets play an essential part in the production process of electronic components. Making sure that the reliability and quality of solder joints are essential to the longevity and functionality of electronic gadgets. Here are the guidelines for constructing and utilizing SMT Reflow and wave soldering pallets

- Materials Selection: Select substances that are able to withstand extreme temperatures and the harsh chemicals of soldering. The most common materials are high temperature plastics, such as PEEK, Ultem, or composite materials such as fiberglass-reinforced epoxy.

- Create a pallet that is designed for Thermal Stability: Plan pallets that have the stability of thermal heat in mind. This will stop deformation and warping from the soldering. Make sure that the heat is evenly distributed over the surface of the pallet to prevent uneven soldering parts being placed.

- Optimized Layout: Plan the pallet layout in order to improve efficiency of the soldering procedure. Place components with similar thermal profiles in order in order to guarantee an even cooling and heating. Make sure that the distance between components is optimized so that solder does not bind or cause tombstoning.

- Surface Finish: Pick the finish you prefer that encourages solder wetting, and also prevents solder bridges or balling. There are smooth, non-reactive finish options like Teflon or special coatings such as anti-static coatings that prevent Electrostatic discharge (ESD) harm.

- Component Nesting: Create pallets with nesting capabilities that are secure that will hold SMT components securely throughout the soldering process. Be sure to have the proper clearance between components to avoid damage or misalignment while unloading and loading pallets.

- Easy Cleaning: Develop pallets with easy cleaning features to eliminate flux residues as well as the traces of solder after. Select materials and finishes that work with the cleaning chemicals commonly used in manufacturing electronics.

- Modularity and reuse: Develop pallets with modularity and reusability in order to reduce costs and environmental impacts. Look into interchangeable or modular pallets that are able to be adapted to different layouts of boards or sizes of components.

- Traceability and Documentation: Set up an automated system to track utilization of the pallet and maintaining history to guarantee traceability and conformity with the quality standards. Keep detailed records of pallet design, material, and manufacturing procedures for reference in the future.

- Testing and Validation: Conduct extensive testing and validation of designs for pallets to verify the compatibility of your designs with certain soldering processes and assembly specifications. Test prototypes and analyze to determine and resolve any design or performance issues.

- Continuous improvement: Continually assess and review the pallet’s performance in order to determine areas of improvements. Ask for feedback from operators in the production process and process engineers, to pinpoint points for improvement and further refinement.

SMT reflow and Wave soldering pallets have a crucial role to play to ensure high-quality and efficient production processes for electronics assembly. These pallets function as platforms that securely keep elements in position during soldering to prevent misalignment or damages.

When reflowing SMT, pallets aid in the precise placement of components mounted on the PCB. This allows for constant heat and soldering throughout the board. This improves the durability of the delicate parts and guarantees secure electrical connections.

In the same way, when using waves soldering, the pallets facilitate the easy flow of PCBs through the melting solder wave guaranteeing uniform soldering of through-hole parts without the threat of defects or solder bridges.

Utilizing your pallets to its maximum capacity requires a variety of aspects to consider. The first is choosing the correct pallet material and style will ensure that they are able to stand up to intense temperatures as well as chemical exposure to the soldering process. In addition, maintaining and clean-up of pallets increases the life of their components and avoids any contamination that could impact the quality of soldering.

In addition, using effective pallet management systems like tracking use as well as maintenance schedules and inventory levels, could simplify manufacturing processes and decrease time to repair. A regular assessment of the performance of your pallet and ongoing improvement efforts like refining designs for pallets or procedures based on the feedback of customers and analysis of data could further increase efficiency and effectiveness.

In the end, SMT reflows and waves soldering pallets are essential tools to ensure consistent and stable soldering outcomes in electronic production. Utilizing pallets to the maximum extent possible by making sure that the pallet is selected with care, maintained, and administered, producers are able to improve efficiency, decrease expenses, and maintain the most high-quality standards for the manufacturing process.

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly, and box-build suppliers meeting your Required Electronic Manufacturing Capability, capacity, and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronics Product Design and Electronic Manufacturing Services Partner Profile:

Argus Systems (AESPL) Electronics Manufacturing – PCB, PCBA, Cable Assembly, Box Build, Testing.

Argus Systems (AESPL) Product Engineering – Electronics system design Services & consulting

Contact sales@sysargus.com to discuss How Argus Systems can support for your Electronics Design Design and Electronics Manufacturing Services ( EMS) Requirements.