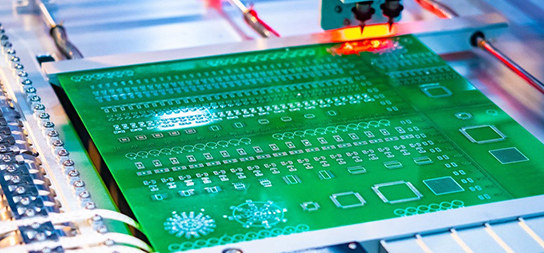

Automated Optical Inspection (AOI) is an incredibly valuable tool for manufacturers of printed circuit board (PCB) assemblies. AOI is a form of automated visual inspection that uses high-resolution cameras to detect any defects or discrepancies in the PCB assembly process.

By using AOI, manufacturers can increase the accuracy and reliability of their PCB assemblies, as well as reduce costs associated with manual inspection.

In this blog post, we will discuss how automated optical inspection can benefit your PCB assembly process.

Introduction to AOI

Automated Optical Inspection (AOI) is a powerful and cost-effective tool for detecting defects in printed circuit boards (PCBs).It uses visual inspection technology to identify flaws, such as incorrect components placement, poor soldering, and missing solder joints. In addition to being highly accurate, AOI systems can be set up quickly and require minimal operator intervention.

The main purpose of AOI is to quickly and accurately detect any defect in the PCB assembly. To achieve this, the system takes multiple high-resolution images of the board, captures all features on the board, and then compares them with a reference file.

If any discrepancies are found, they are flagged so that they can be repaired or replaced. This process is faster than manual inspection and allows manufacturers to save time and money.

AOI systems are also used for quality control purposes. They are used to detect errors at the earliest possible stage, allowing manufacturers to prevent costly rework and avoid product recalls. AOI can be used for both visual inspection and electrical testing of assembled PCBs.

Overall, AOI offers manufacturers a powerful tool for quickly and accurately detecting defects in their products. It is relatively easy to use and can save time and money in production.

Working Principle of AOI Test

Working Principle of AOI Test

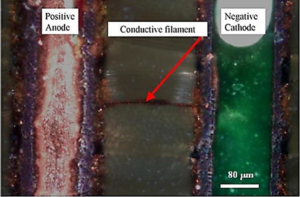

Automated optical inspection (AOI) is a type of automated test that is used to inspect printed circuit boards (PCBs). It is used to detect any defects or abnormalities on the PCBs that may not be visible to the naked eye. AOI uses light and cameras to scan each PCB layer in order to find potential errors.

AOI is based on the principle of visual inspection: it looks for irregularities such as missing components, misaligned components, solder bridges, and other imperfections. The process involves using an imaging system and comparing it to a set of predefined criteria. The criteria can be set by the user, based on their specific requirements.

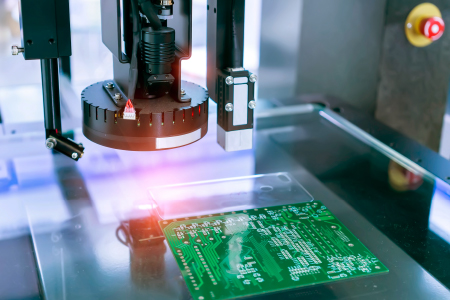

AOI works by illuminating the PCB with light from various angles and then capturing images of each layer. These images are then compared to a predetermined set of criteria, which is used to determine whether a defect exists or not. If a defect is found, the AOI system will alert the user, who can then take the necessary steps to rectify the problem.

The process of AOI testing is relatively fast and accurate, making it an ideal solution for high-volume manufacturing. Additionally, it eliminates human error and increases throughput, resulting in improved quality control. It is also cost effective, as it eliminates the need for manual inspection and reduces costly rework and scrap costs.

When should you use Automated Optical Inspection (AOI)?

Automated Optical Inspection (AOI) is an effective way to reduce the cost and time of manual inspection. AOI can help detect defects in your PCB assembly process quickly, efficiently, and reliably.

AOI is recommended for any applications that require high accuracy and precision, especially in areas with high-density components and fine-pitch components. Additionally, AOI can be used when manual inspection is either too difficult or too time-consuming.

AOI should also be used when traditional visual inspection methods cannot identify certain types of defects. For example, optical inspection may be able to detect a missing component or incorrectly placed component, but it cannot detect electrical shorts or open circuits, which require specialized test equipment.

Finally, automated optical inspection can be used for production ramp-up or when you need to quickly inspect multiple board designs. AOI machines can store various board designs in memory and can inspect different boards rapidly and accurately. This makes it an ideal solution for short-term production demands or for prototypes.

How is AOI implemented?

Automated Optical Inspection (AOI) is an automated process that uses computer vision and image processing techniques to inspect printed circuit boards (PCBs) for defects.

This technology uses advanced cameras and software to examine the quality of the PCBs. It can detect a wide range of problems, from incorrect soldering, to improper parts placement, or to faulty components.

The AOI system consists of several components, including a camera system, imaging software, and a light source.

The camera system is used to capture images of the board at various angles and resolutions. The imaging software then analyses the images and highlights any defects it detects. The light source provides the necessary illumination for the cameras to capture a clear image of the board.

The implementation process begins with creating an accurate 3D model of the board that will be inspected. Once the model is created, it is inputted into the imaging software, which will then use it as a reference when inspecting the board. The software will look for discrepancies between the 3D model and the actual board, flagging any issues it finds.

The operator can then review these findings and make any necessary repairs or corrections.

Once the AOI system is set up and configured, it can quickly inspect multiple boards in a short period of time, greatly increasing the efficiency of PCB assembly processes.

AOI systems are also capable of detecting even very small defects that may not be visible to the human eye. In addition, AOI systems can be programmed to be highly sensitive to certain types of defects, allowing for very precise and accurate inspection results.

How much does Automated Optical Inspection cost?

The cost of automated optical inspection (AOI) for PCB assemblies depends on a variety of factors such as the complexity of the design, the production volumes, the accuracy and speed of the AOI, and the size and shape of the boards being inspected.

Generally, the cost of an AOI system can range from a few thousand to several hundred thousand dollars. For small businesses, an entry-level system may be sufficient; however, it is important to note that more complex systems with higher accuracy and speed come with a higher price tag.

When shopping for an AOI system, it is important to consider all the factors mentioned above, as well as any additional features or benefits offered by different vendors. Additionally, it is important to factor in the cost of training and support for the system, as well as any extra costs associated with ongoing maintenance or repairs. The cost of AOI will also vary depending on whether you buy a used system or a new one.

Finally, the cost of AOI can also depend on whether you outsource the inspection process to an outside vendor or use internal resources. If you choose to outsource, be sure to include all fees associated with the vendor in your total cost estimate.

In summary, while AOI systems come with a significant price tag, they offer greater accuracy, faster throughput, and higher quality than traditional manual inspection methods. Investing in an AOI system is a worthwhile investment that can save your business time and money in the long run.

How does Computer Vision system with AI software platform compare to AOI?

Computer vision system with AI software platform helps organizations optimize the visual inspection process for their printed circuit boards (PCBs). It uses high-resolution cameras and image recognition algorithms to detect any flaws or defects in a PCB assembly. Unlike Automated Optical Inspection (AOI), which relies on human inspectors to review images of components, AI based system automates this process by using a computer vision system.

It has a number of advantages over traditional AOI systems. For one, it is much faster, reducing inspection times from hours to minutes. This can significantly speed up production cycles, saving time and money. Additionally, it provides a higher level of accuracy, with fewer false positives and negatives. It also allows you to monitor and track your inspection process, providing insight into the effectiveness of your quality assurance measures. Overall, it provides a more efficient and accurate way to inspect your PCBs than traditional AOI systems. It automates the process, reduces inspection times, increases accuracy, and provides real-time data about the quality of your production. As a result, it is becoming an increasingly popular choice for companies looking to maximize the efficiency and accuracy of their PCB inspection processes.

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly and box build suppliers meeting your Required Electronic Manufacturing Capability, capacity and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Systems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.

CerraSystems Inc – HDI PCB, Rigid Flex PCB, RF PCB