Quality Standards in Electronics Manufacturing

The world of electronics manufacturing is fast-paced and dynamic. With the relentless pace of technological advancements, consumers expect products that are not only innovative but also reliable and safe. This is where quality standards come into play. In this comprehensive blog, we will explore the significance of quality standards in electronics manufacturing, various standards that are crucial, and how they impact the industry.

Importance of Quality Standards in Electronics Manufacturing

Ensuring Product Safety

The electronics manufacturing industry is built upon trust. Consumers need to be confident that the devices they purchase, from smartphones to medical equipment, are safe to use. Quality standards help manufacturers identify potential hazards, implement safety measures, and reduce the risk of product-related injuries or accidents.

Meeting Customer Expectations

In a highly competitive market, meeting customer expectations is paramount. Quality standards drive manufacturers to consistently produce products that perform as expected, adhere to specifications, and provide superior user experience. Customer satisfaction often leads to brand loyalty and repeat business.

Legal and Regulatory Compliance

Various laws and regulations govern the electronics industry. Quality standards ensure that manufacturers comply with these requirements. For instance, the Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electronics. Compliance with RoHS, along with other regulations like the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH), is essential to avoid legal consequences.

Key Quality Standards in Electronics Manufacturing

ISO 9001: Quality Management Systems

ISO 9001 is a globally recognized standard for quality management. It focuses on processes that help organizations consistently meet customer and regulatory requirements. Electronics manufacturers often adopt ISO 9001 to enhance their overall quality management systems, covering design, production, and delivery processes.

ISO 14001: Environmental Management

ISO 14001 is crucial for electronics manufacturers committed to environmental sustainability. It provides a framework for organizations to minimize their environmental impact. Given the increasing focus on eco-friendly electronics, ISO 14001 certification is gaining significance.

IPC-A-610: Acceptability of Electronic Assemblies

The IPC-A-610 standard sets criteria for the acceptance of electronic assemblies. It covers everything from component placement to soldering, ensuring that electronics meet established quality levels. Adhering to this standard is essential for consistent product quality.

RoHS and REACH Compliance

RoHS restricts the use of hazardous materials in electronics. Compliance ensures that electronic products are safe and environmentally friendly. REACH, on the other hand, governs the use of chemicals in products, including electronics. Adherence to these regulations is vital for international market access.

UL Certification

Underwriters Laboratories (UL) certification is well-known for safety and performance testing of electronic products. Products that bear the UL mark have met rigorous quality and safety standards. This certification assures consumers that the product is safe for use.

ANSI/ESD S20.20: Electrostatic Discharge Control

Electrostatic discharge (ESD) can damage electronic components during manufacturing and use. ANSI/ESD S20.20 outlines procedures and guidelines for ESD control programs. Compliance with this standard is essential to protect sensitive electronic components.

Quality Standards and the Manufacturing Process

Design and Prototyping

Quality standards should be integrated into the design phase to ensure that product specifications align with industry requirements. Prototyping, an integral part of this phase, helps identify and address potential quality issues early.

Component Sourcing and Traceability

Quality standards require manufacturers to maintain a robust system for tracking and tracing components throughout the supply chain. This traceability ensures that only approved and genuine parts are used, reducing the risk of counterfeits.

Assembly and Testing

During the assembly phase, adherence to quality standards guarantees that components are correctly placed and soldered. Rigorous testing is performed to identify defects and ensure that the final product meets all quality criteria.

Supply Chain Management

Quality standards extend beyond the manufacturing facility and into the supply chain. Manufacturers must work with suppliers who also meet specified quality standards to maintain the integrity of the components and materials used.

Adoption Challenges and Benefits

Overcoming Resistance to Change

Adopting quality standards may face resistance from within an organization. Some may view the process as disruptive or costly. However, the long-term benefits often outweigh the initial challenges, including improved product quality and compliance with regulations.

Competitive Advantage and Market Access

Manufacturers that adhere to quality standards gain a competitive advantage. They can access international markets with ease, demonstrating a commitment to quality and safety, which is a significant selling point.

The Impact of ISO 9001 on Product Quality

Numerous electronics manufacturers have reported substantial improvements in product quality after implementing ISO 9001. The standard helped them streamline processes, reduce defects, and enhance customer satisfaction.

RoHS Compliance in the Electronics Industry

The electronics industry’s shift towards RoHS compliance has led to the development of lead-free manufacturing processes. This shift has not only improved product safety but also reduced environmental impact.

Quality Standards in Electronics Manufacturing

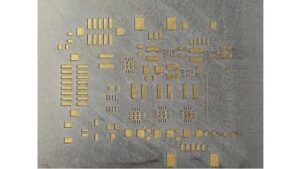

PCB Assembly and Wire Harness Standards

- MSD components pre-baked in accordance with the IPC/JEDEC-J-STD-033, prior to the PCB assembly.

- PCB Pre-baking and Pre-assembly QC in accordance with IPC-1601A.

- Soldering in accordance with IPC-7530A STD.

- Assembly, Re-work & QC in accordance with the IPC-A-610-II/III and IPC- 7711/21 STD.

- PCBA’s are cleaned, considering the complexity & presence of sensitive components Accordance to IPC-CH-65 and is conforms to IPC J-STD-001E standard.

- Conformal coating & potting are performed according to the IPC-CC-830 & J- STD-001 standard.

- Cable and Wire Harness Manufacturing as per IPC/WHMA-A-620 standard.

PCB Manufacturing standards

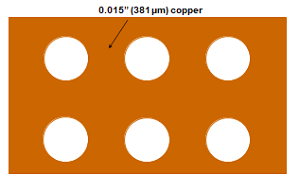

- UL approval 94-V-0- for double sided, Multilayer’s and Rigid flex PCB

- IPC Class 1: Consumer products, including TV sets, toys, entertainment electronics, and non-critical consumer or industrial control devices

- IPC Class 2: General industrial, including computers, telecom equipment, business machines, and non-critical military applications

- IPC Class 3: High reliability, including equipment where continued performance is critical, life support & Military.

- IPC Class 3A: Performance Specification for Space & Military

- IPC 6011/6012 Type 1 – Single–Sided

- IPC 6011/6012 Type 2 – Double-Sided

- IPC 6011/6012 Type 3 – Multilayer without blind & buried vias, High Reliability

- IPC 6011/6012 Type 4 – Multilayer with blind & buried vias, High-Reliability Advanced

- IPC 6011/6012 Type 5 – Copper core Multilayer without blind & buried vias

- IPC 6011/6012 Type 6 – Copper core Multilayer with blind & buried vias

- MIL-PRF-31032/5 Type 1 – Single–Sided

- MIL-PRF-31032/5 Type 2 – Double-Sided

- MIL-PRF-31032/5 Type 3 – High Reliability – Rigid Multilayer without blind or buried vias

- MIL-PRF-31032/5 Type 4 – High-Reliability Advanced, Rigid Multilayer with blind & buried vias

- MIL-PRF-31032/5 Type 5 – Rigid Multilayer without blind or buried vias with metal core or metal backing external heat-sink.

- MIL-PRF-31032/5 Type 6 – Rigid Multilayer with blind or buried vias with metal core or metal backing external heat-sink.

- MIl-P50884 Type-4 for Rigid-flex PCB

The Future of Quality Standards in Electronics Manufacturing

Emerging Technologies

As new technologies like 5G, IoT, and artificial intelligence continue to shape the electronics landscape, quality standards will evolve to address the unique challenges and opportunities they bring.

Sustainability and Ethical Practices

Sustainability and ethical manufacturing practices are becoming increasingly important. Quality standards will incorporate requirements for responsible sourcing of materials and environmentally friendly manufacturing processes.

Conclusion

Quality standards in electronics manufacturing are the cornerstone of producing safe, reliable, and innovative products. Adherence to these standards is not just a matter of meeting legal requirements but also a strategic decision to gain a competitive edge and build consumer trust. As the industry evolves, so too will the quality standards, ensuring that electronics continue to be at the forefront of technological innovation while adhering to the highest quality and safety standards.

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly, and box-build suppliers meeting your Required Electronic Manufacturing Capability, capacity, and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Systems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.