Aluminum and copper Heat sink PCB

- To operate efficiently and ensure reliability, heat must be removed from heat-generating power components.

- As a result of faster speeds, reduced format, and more devices being populated on PCBs, more heat is being generated that must be removed for efficient operation.

- The move to sustainable energy increased the demand for energy management electronics which also create much heat because of the high electrical currents used on these applications (Power inverters for solar and wind energy, powertrain electronics for HEV).

- Thermal management through various applications aids in directing heat away from heat-generating system components.

- The following is a review of various thermal management approaches, applications, and capabilities that can be supported.

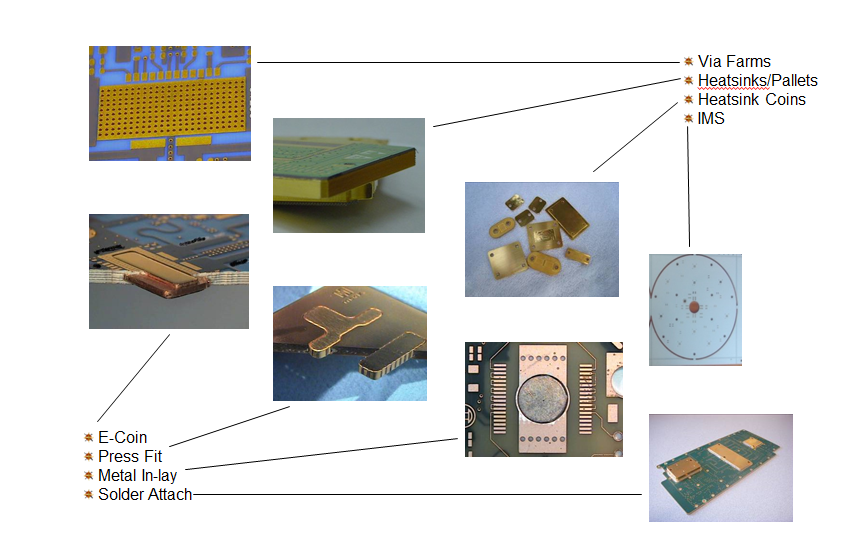

Thermal Management Types Offered

PCB Thermal Management –Pressure Sensitive Adhesive for Aluminum and copper

Pressure sensitive adhesive (PSA) is a lower-cost option for attaching pallets/coins or plate-heatsinks to a PCB where electrical conductivity is not required.

Pressure Sensitive Adhesive advantages

- Does not require a heat source for bonding, thus simplifying the bond process

- Bond to low surface energy substrates or surfaces

- Resists dielectric breakdown

- Relatively high Thermal resistance of the tape

- Can meet aerospace and medical requirements

- Used in high volume in automotive applications (surface attached heatsinks)

- Old technology. Probably less demand in the future as customers move to alternatives.

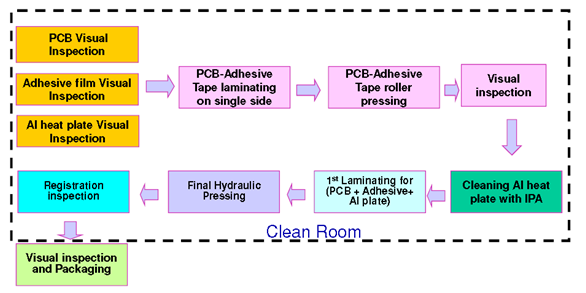

Aluminum-plate Heatsink Process Flow.

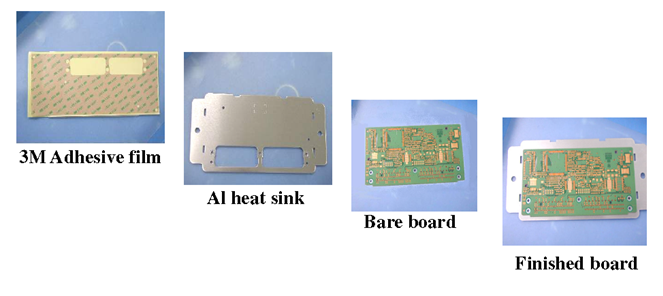

Aluminum-plate Heatsink: Raw material and production

Raw material and production

Main Process equipment used for ‘Aluminum-plate Heat-Sink’

PCBA Adhesive Tape roller pressing

1st laminating For PCB , Adhesive and Al plate

Final Hydraulic pressing

Copper Heat-Sink board

Copper Heatsink (heat-spreader).

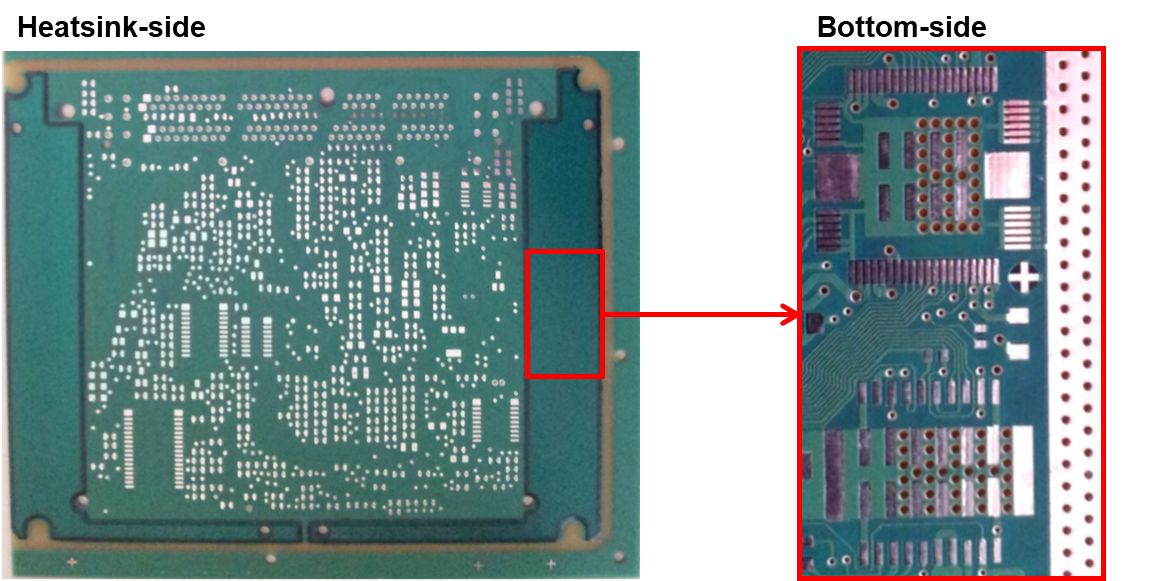

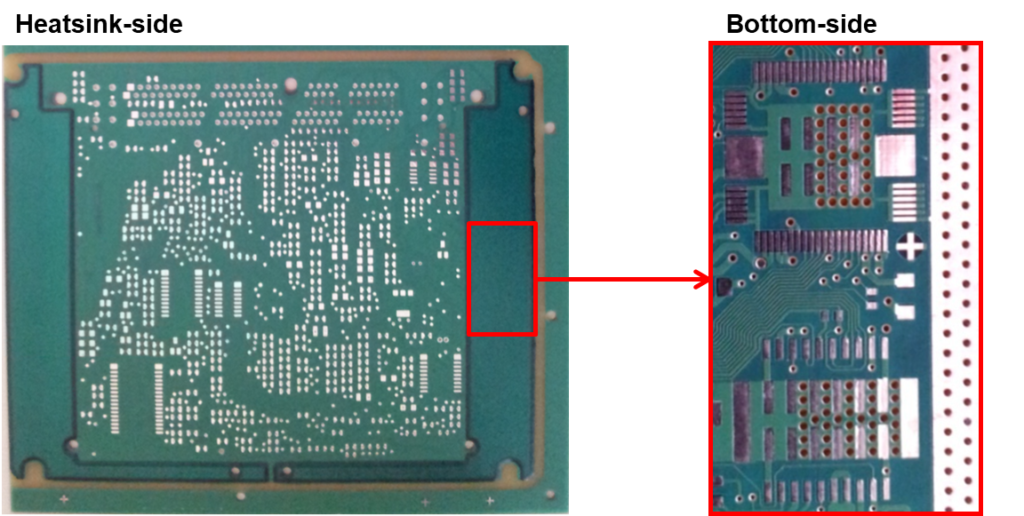

On the bottom side, the component housing is soldered to the GND plane which contains thermal-Vias to conduct the heat to the heat sink.

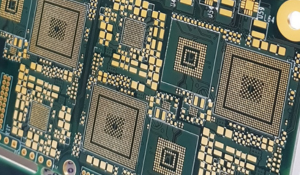

- Heat Sink Pick and Place machine is used to assemble copper heat-sink to PCB.

- These copper heat sinks are much thinner and smaller than the aluminum-plate heatsinks so suitable for Pick and Place process.

- The automated process includes both ‘pick and place’ and ‘pressing’ of the copper heatsinks.

Main Process equipment used for the automated ‘Copper Heat-Sink’ process.

Pick and Place

Pressing

Screen printing

Customer test requirements for the ‘copper Heatsink process’ includes

- Voltage test (no electrical flashover at room temperature and 100V)

- Solderability test (no delamination in the solder bath 288ºC/20sec.)

- Adhesion test (the adhesive strength must be > 0.5N/mm)

- Temperature cycle test (no delamination in 200 test cycles)

PCB Thermal Management – Heat Sink Paste

- Heat Sink Paste (HSP) Thickness: 0.15mm

- Position tolerance (e.g. HSP to PCB): /-0.2mm

- Application by means of the silkscreen printing process

- Can be printed with the suitable geometry needed

- Printing and curing in two steps (75um per step )

- Final layer thickness 160 um

- Excellent heat conductivity (2 W/mk)

- High Isolation [ 30 KV/mm ]

- Resistant against AFT/Isolation layer of Cu Structures against AFT

Heat Sink Paste (HSP) Examples

4L HSP PCB

4L HSP PCB

6L HSP PCB

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly, and box-build suppliers meeting your Required Electronic Manufacturing Capability, capacity, and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Systems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.