Introduction to electronic packaging

Electronics are often fragile and expensive, it’s critical to know how to pack and ship them safely. Take a look at the guidelines below for properly packaging electronics so you may avoid costly damages and returns when shipping electronic items.

This is the first post in the series ” Supplier Packing Standards”

This guideline has been developed to demonstrate packaging best practices that suppliers are expected to adopt in order to best position themselves to provide defect free parts, maximize production efficiency and ensure safety while minimizing overall packaging and transportation costs to meet each customer plants logistics and operational requirements

Parts Quality

- Supplier is responsible to ensure that packaging delivers parts to the final point of use, in a production-ready and damage-free condition, assuming normal handling, transportation, storage, and in-plant

- Some parts packaging may require inserts, bags and separators for protection. That must be included in the packaging

- Some packaging systems and components may require additional protection such as corrosion, surface abrasions, or static build-up.

Packaging Characteristics

- Must fit all variants and ensures efficient transport utilization

- All returnable containers must have a cover lid

- When applicable, include additional bags for easy repack

- When expendable, the content must fit the internal dimensions of any KLT container of standard size, whether European or American.

Packaging Backup

Suppliers are responsible for the design and procurement of expendable back-up packaging that is of a similar footprint (not to exceed returnable footprint) and part density. This expendable back-up design is required to be completed prior to the product launch. If returnable packaging is the primary solution, the supplier must get plant approval when shipping expendable back-up packaging.

Packaging Improvements

Suppliers should take an active role in the ongoing analysis of packaging methods, materials, and cost reduction. If a lower total cost solution exists that is not compliant with the guideline, the supplier should contact Client and provide an analysis for review, each proposal will be reviewed case by case basis. Alterations to the approved packaging may be requested by the receiving plant, suppliers shall respond quickly and manage packaging changes immediately.

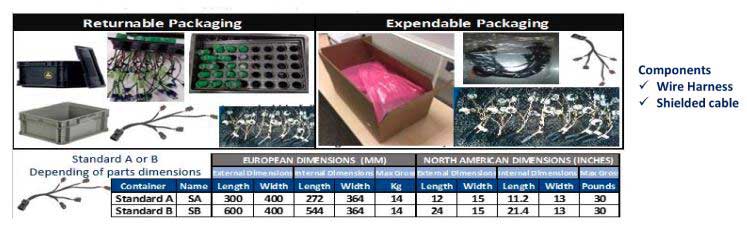

Returnable or Expendable

Due to environmental, cost and quality considerations, prefer the use of returnable packaging where feasible and a lower total cost solution.

Returnable if:

Distance from supplier to Customer plant < 1500 Km

Expendable if:

Distance from supplier to Customer plant > 1500 Km

Standard Containers

As customers prefers the use of returnable packaging most of the parts are compatible with standard (A&B) size containers, available from several suppliers.

Container height is not standard, however, 220 mm (9 in) is the preferred height.

Non-standard Containers

For those components that the dimensions do not fit in a standard size container, non-standard container options are available

Electronic Components Packaging

For electronic components the use of ESD containers is mandatory and each container should have their own lid, every KLT should include ESD lid , and the packaging must be designed with the following characteristics:

- ESD Standard Container with closed grips and ESD cover Lid.

- ESD thermoformed trays

- ESD tape to lock it

- ESD plastic pallets

- ESD Plastic Bag (for expendable packaging)

- When expendable: the content (thermoformed trays) must fit to the internal dimensions of any containers whether European or

5.2 Wire Harnesses Packaging

For wire harness, the use of ESD containers is optional. However, proper protection to the parts is needed, and design should follow the following characteristics:

- Standard container with cover Lid

- Thermoformed trays (optional depending on the shape of the part)

- ESD protected bubble foil or individual bag (depending on the shape of the part)

- When expendable: ESD plastic bag and the content (thermoformed trays) must fit to the internal dimensions of any containers whether European or American.

To know more please read the next part of the article which is the second post of the series ” Supplier Packing Standards”

EMSxchange Enables you to find a manufacturer meeting your Required Manufacturing Capability, capacity, Certification Criteria from a global electronic manufacturing supplier base. Our manufacturing engineering and supply chain management ensure that all the manufacturing suppliers who register on Manufacturing platforms are Reviewed, evaluated, and audited as per their published capability and performance matrix. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.