Introduction to electronic packaging

Electronics are often fragile and expensive, it’s critical to know how to pack and ship them safely. Take a look at the guidelines below for properly packaging electronics so you may avoid costly damages and returns when shipping electronic items.

This guideline has been developed to demonstrate packaging best practices that suppliers are expected to adopt in order to best position themselves to provide defect free parts, maximize production efficiency and ensure safety while minimizing overall packaging and transportation costs to meet each customer plants logistics and operational requirements

This is the third post in the series ” Supplier Packing Standards”

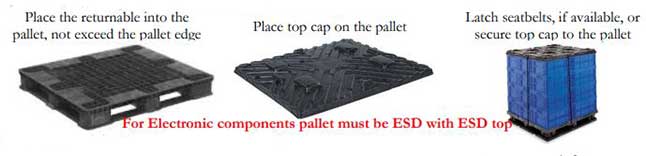

Palletizing rules when returnable

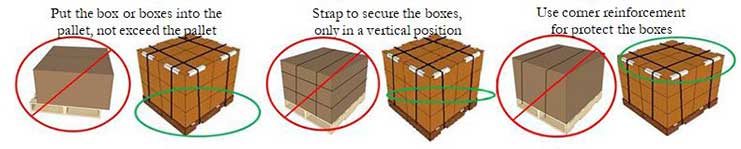

Palletizing rules when expendable

Wood Pallets

Pallets must provide a four-way fork entry and be double-face non-reversible wood construction. 3-1/2 inches under-clearance on two opposite sides with a minimum of 2 inches under-clearance on the remaining two sides is required.

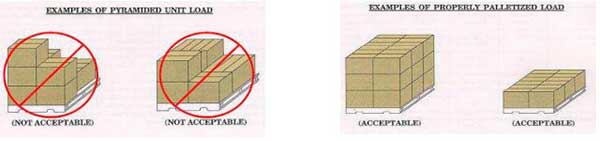

Palletizing Acceptable and Unacceptable Examples

The information below is meant to help illustrate to the supplier what is considered acceptable and unacceptable by providing examples of actual shipments.

labeling Standard

The quality of the information on labels is essential. Bar code labels are required and used to eliminate opportunity for error. Errors made because of label deficiency are serious in nature.

International Shipments

Load Stability

All packs must have sufficient vertical strength and stability to withstand tiered heights to help minimize freight and storage cost. Proper unitization is critical to insure maximum load stability. Stretch/shrink wrap is a preferred method of unitization. Banding, seatbelts or other stabilizing techniques can be utilized to secure palletized loads.

The supplier must ensure the method will provide the required unitization and stabilization. Nailing, stapling or gluing is not an acceptable method for securing the loads.

Shipping Unit Loads must be able to be stacked 2200mm (86”) high in storage and in transit.

No pyramid loads are ever acceptable as they reduce the load stackability, will not allow Varroc Lighting Systems to maximize freight, and risk product damage.

Containers must be oriented so that they will fully utilize the length and width of the pallet. To help insure vertical integrity containers must not overhang the edge of the pallet

Transportation Considerations

Packaging must be designed for transport logistics that are common for overseas supply chains. Suppliers should consider all possible modes of transit including truck, rail, ocean and potentially air freight.

Pallet Surface and Cube Utilization

The pallet surface utilization is critical to insure pallets can be consolidated and stacked properly. Proposed cartons should cover a minimum of 90% of the pallet surface (If the proposed packaging does not meet this minimum target it may be rejected and a better proposal requested.

For all intercontinental shipments; transportation has the goal to utilize a minimum of 90% of the available shipping space inside the sea container. If the proposed packaging does not meet this minimum target it may be rejected and a better proposal requested.

Standard Intercontinental Pallets

The pallet size is predicated on commonly used sea container interior dimensions:

- Width: 2337 mm (92 inches)

- Minimum door opening height: 2286 mm (90 inches)

- Lengths: 5,892mm (232 inches)- 20 foot container 12,014mm (473 inches)- 40 foot container

The recommended AIAG pallet size for Intercontinental shipments is 1140mm x 980mm x 125mm (45.0 inches x 39.0 inches x 5.0 inches)

The AIAG standard pallet footprint shall be used for all intercontinental shipments to customer sites. Regardless of style, all pallets must allow for 4-way access to aid in the handling and storing of each unit load. Winged pallets should not be used.

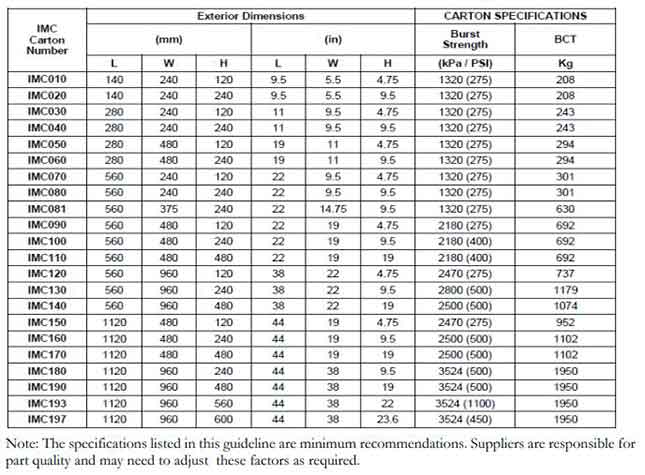

Standard Intercontinental Carton Sizes

The sizes listed below are the most common standard carton sizes to be used for Intercontinental shipments.

Other sizes can be used but must properly and efficiently cube out the export pallet footprint. The full unit load height, including the pallet and all cartons, can not exceed 1100mm (43 inches).

Carton Performance

Stacking strength shall be a value that adequately protects the contents of the carton through a complete transport cycle. Boxes stacking strength shall be verified through a Box Compression Test (BCT). Hand holes in carton reduce BCT values and may require stronger material. Carton toughness shall be specified with a minimum value that adequately protects the contents of the carton through a complete transport cycle. Carton toughness shall be verified for corrugated fiberboard through a Burst Strength (BS) test.

This minimum value assures performance when the carton is shipped either non-palletized or in a pallet-loads of mixed cartons.

Other factors that need to be taken into consideration that can degrade carton performance include:

- Leaking sea containers

- Multiple shipments of product

- Long term storage

Pallet Loading

Cardboard boxes are to be palletized in full layers only (no “pyramiding”), to allow tiered unit loads in transit and storage. If release quantities are inadequate to complete full layers, additional carton must be shipped empty (and marked as “empty”) in order to complete a full layer.

Suppliers must size all cartons to fully utilize length and width of the pallet. Cartons must not overhang the pallet base.

Strippable reinforced tape or spot gluing are the only acceptable methods for carton closure. If gluing is selected, glue transfer to the part surface is unacceptable.

Shipping unit loads should not exceed 1100 mm (43 inches), including the pallet, when fully loaded

EMSxchange Enables you to find a manufacturer meeting your Required Manufacturing Capability, capacity, Certification Criteria from a global electronic manufacturing supplier base. Our manufacturing engineering and supply chain management ensure that all the manufacturing suppliers who register on Manufacturing platforms are Reviewed, evaluated, and audited as per their published capability and performance matrix. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.