Conformal Coating for PCB

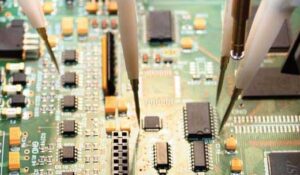

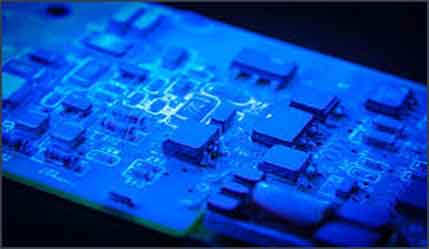

Conformal coating for PCB is the process of applying a thin polymeric film which conforms to the contours of a PCB to protect the board’s components. Typically applied at 25-250 μm thickness, it is applied to the PCBA to protect against moisture, dust, chemicals, shocks and temperature extremes

Methods:

1) Brush Coating

2) Spray Coating

Materials Types:

1) Epoxy

2) Acrylic

3) Silicone

4) Urethanes (Selected as per IPC-CC-830)

Tools Required:

PCBA, Coating Material, Specimen Fixtures, Masking Tapes/Dots, Baking chamber, UV Curing chamber, UV Lamp, ESD Tray, Brush & Liquid solvents (Re-work), Gloves, Goggles & Aprons

Precautions:

- Ensure the dedicated booth is adequately ventilated, follows adequate ambient condition as 18-28 *C / 40- 65% RH and free from FOD’s

- Check and ensure that all utilities, tools & materials are free from unwanted dusts, fumes& moistures

- Ensure the Coating material is not contaminated & maintained as per the TDS (Selected as per IPC-HDBK-830)

- Verify the availability of approved assembly documents indicating the area required to be coated and those which need to be masked

- Unless otherwise specified, coating should be applied to all the electrical components, soldered connections, fab parts such as screw terminals, crimped connections, coils, transformers, screen printed name plates, other metallic parts, etc. Which tend to be subjected to electrolytic corrosion.

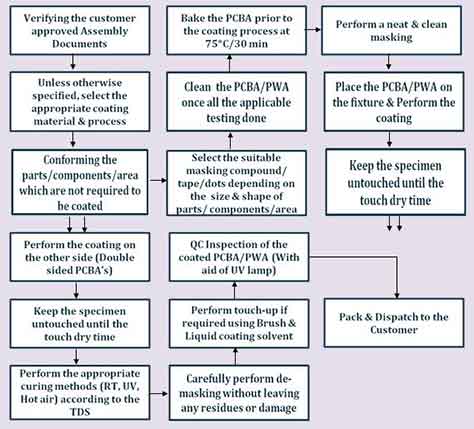

Flow-chart:

Procedure:

- The PCBA or PWA shall be subjected to baking at 75*C/30 Min, prior to the coating application for moisture removal.

- After then, the components & area wherever coating not required shall be masked using masking tape/dots or compound depending upon the size & shape of the component/parts/area.

- Place the specimen onto the fixture and apply the spray coating evenly throughout it in a zigzag manner.

- The aerosol can should be shake vigorously before applying & repeat it periodically

- Maintain a distance of 30-40 cm at angle of 45* to get the best spraying & uniform coating result.

- The specimen should be rotated 90* each time (4 times) after the spraying and kept untouched for about 10 min (Otherwise specified in the TDS) for getting touch dry.

- Repeat the steps 4, 5& 6 for the other side of the specimen & keep untouched for about 10 min (Otherwise specified in the TDS) for getting touch dry.

- After then, it can be subjected to Hot air, RT Curing or UV curing depending on the material type.

- The film thickness of 25-75 μm is sufficient to provide protection.

- To clean the nozzle after application, hold the can upside down, then press the nozzle for few seconds.

- After coating process the masking material should be removed completely by peeling away without leaving any residues or traces of adhesives.

- While de-masking, caution shall be observed to avoid degradation of coating or assembly parts.

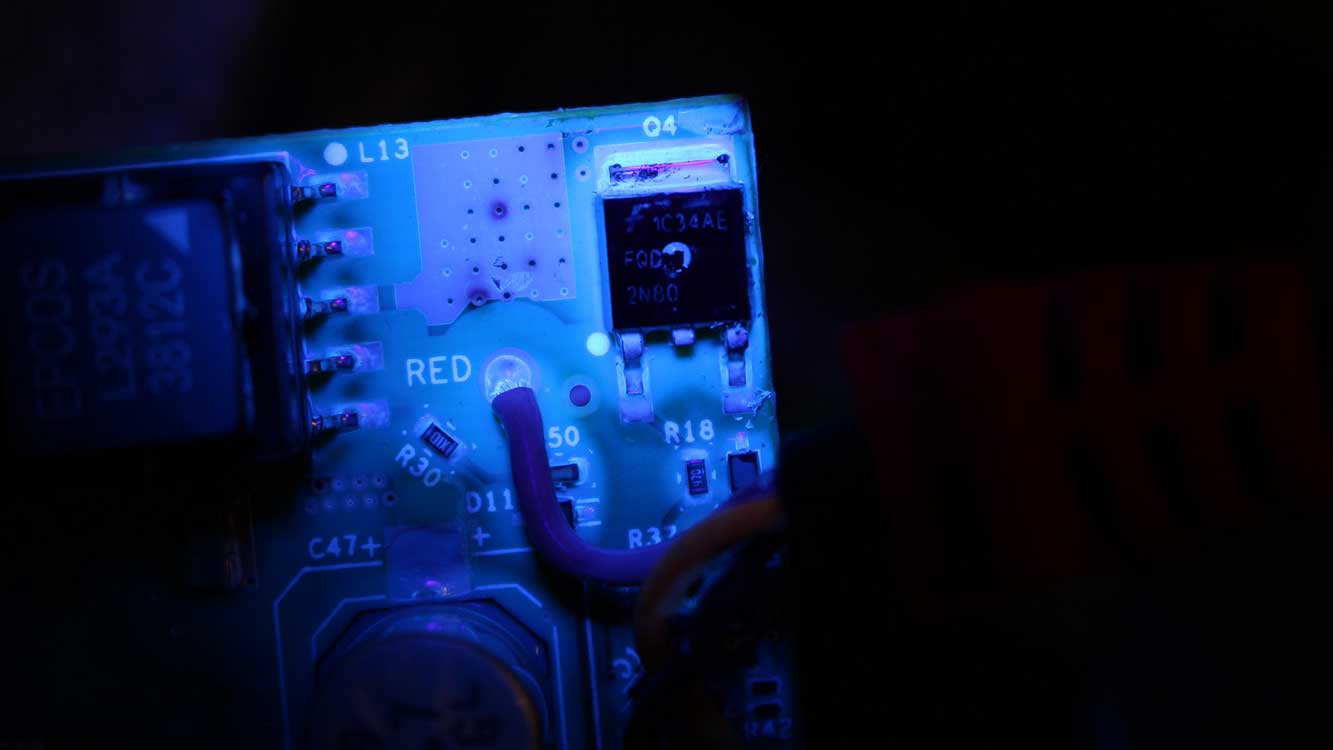

- Visual inspection should be carried out in a dedicated booth to verify the coating quality & uniformity. High intensity long wave UV lamp can also be used for inspection.

- Only In case of rework, the required area should be cleaned with solvents like IPA or acetone for performing the coating process again. For very smaller portions, re-work can be done with brush & liquid coating solvent, provided it should be evenly coated.

Abbreviations:

PCB- Printed Circuit Boards // PCBA- Assembled Printed Circuit Boards // PWA- Printed Wiring Assemblies // TDS- Technical datasheet // FOD- Foreign Object debris // IPA- Isopropyl Alcohol.

EMSxchange Enables you to select a Printed Circuit Board assembly suppliers meeting your Required PCBA Manufacturing Capability, capacity and Certification Criteria from a global PCB Assembly manufacturer base. EMSXchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.