HDVP Engineered Thermal Solutions (ETS)

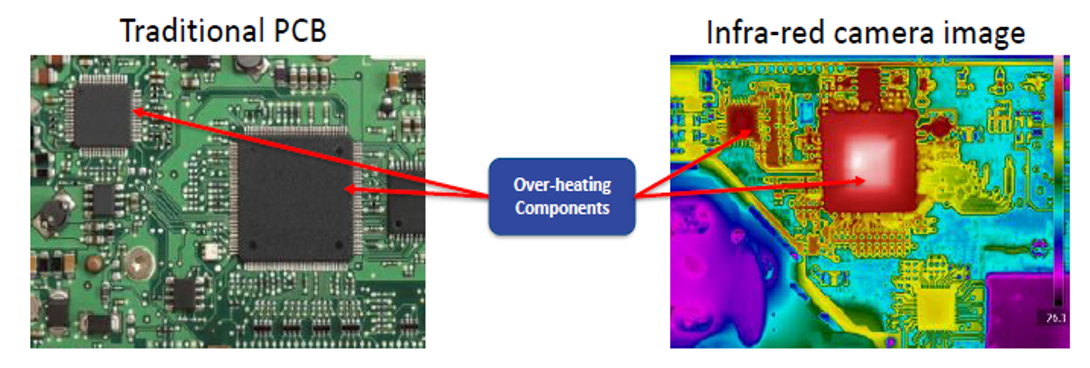

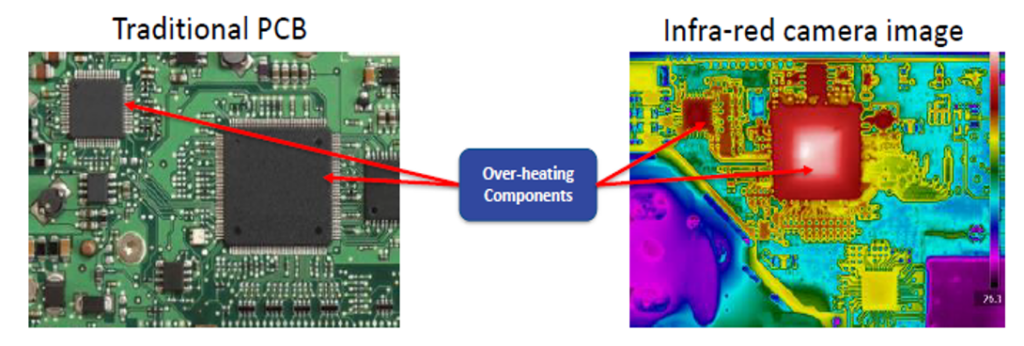

Customer Challenges

- Components mounted on PCB surfaces are overheating

- System density is ever increasing

- Engineers are forced to place more power in less space

- Traditional PCBs have very poor thermal performance.

- Thinner PCBs (0.015” –0.025”) have multiple challenges when fitted with embedded copper coins.

- Engineered Thermal Solutions (ETS) is an innovative approach that improves PCB thermal performance while enhancing layout flexibility.

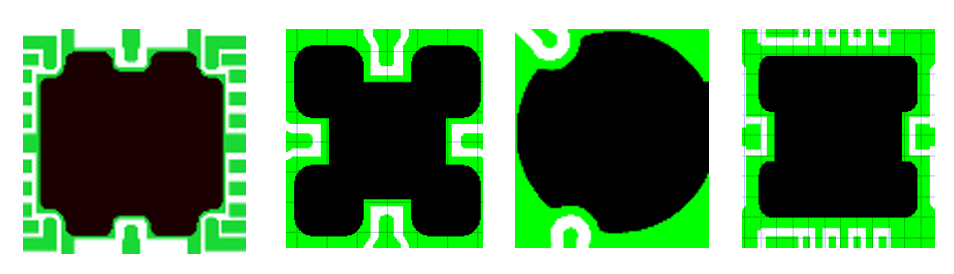

- Drill spacing can be tangentially touching.

- Fill options can be customized

- 100% Cu fill

- Cu plating with Via Fill

- Layout flexibility allows for nearly any geometry to be created;

- Helps to maximize PCB area utilization and achieve smaller designs

- High density via pattern can customize for each thermal load.

- Traces can be routed through multiple angels and layers

- Via patterns can be very small and more flexible versus standard coins

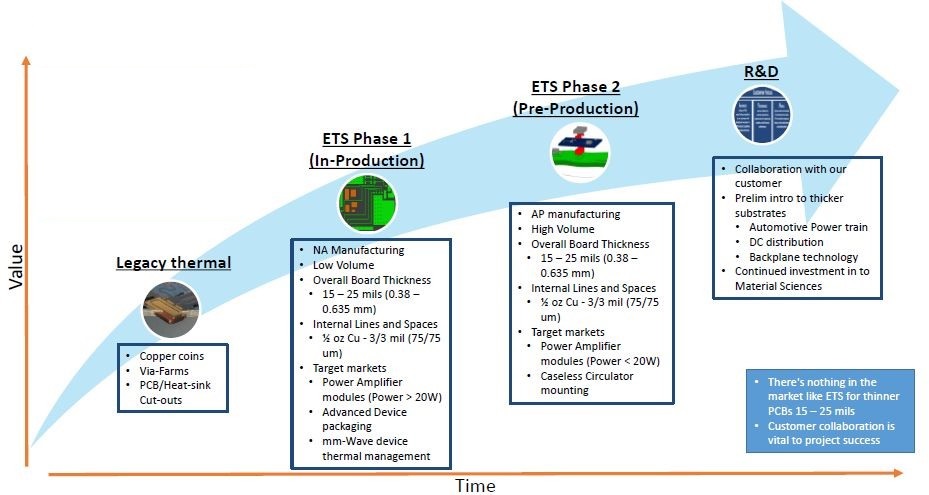

ETS technology is an enhanced replacement of embedded copper coins in thin boards 15 – 25 mils (0.38 – 0.635 mm) thick

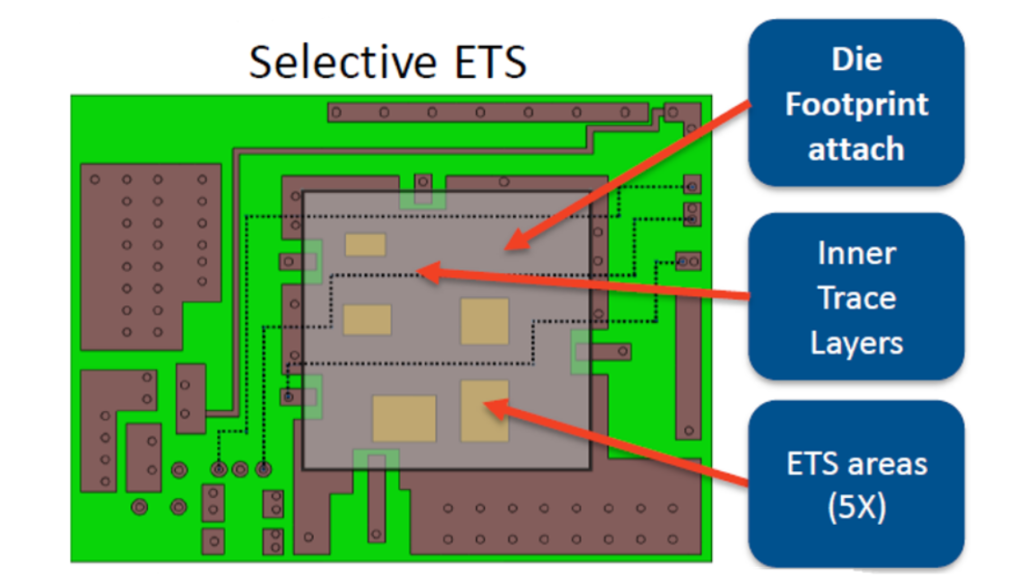

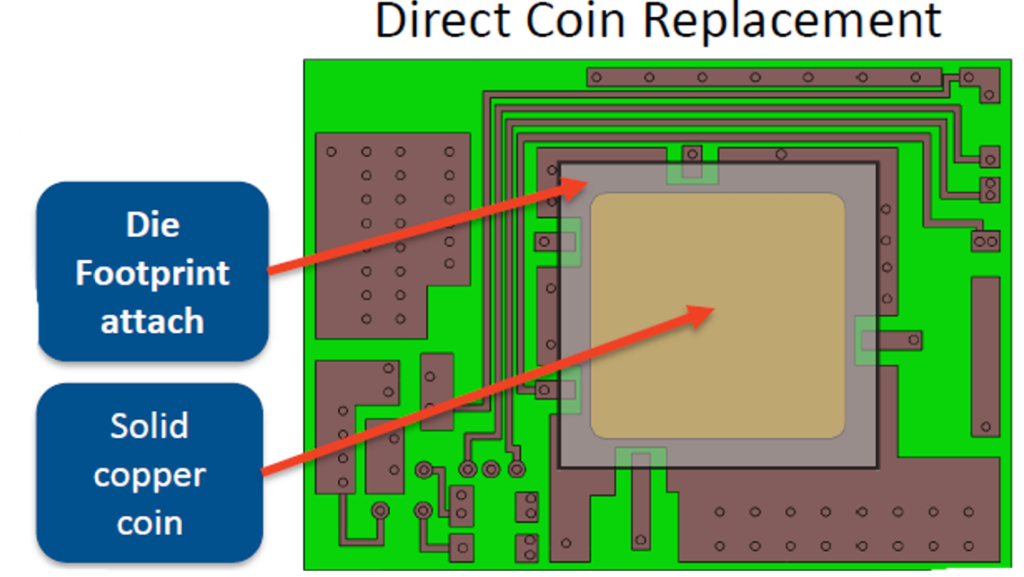

- ETS can be applied in 2 ways

- 1:1 direct coin replacement

- Selective improvement to specific thermal areas

- Selective ETS can be very small and more flexible versus standard coins

- Smallest ETS area – 0.015” x 0.030” (0.38 x 0.76mm)

- As a reference, Coin Size in the image below – 0.24” square (6.1mm)

- Selective ETS greatly improved PCB space utilization

- ETS requires only 30% space required for direct coin replacement (For this application)

- Helps to reduce design size and layer count

Engineering Thermal Solution(ETS)

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly, and box-build suppliers meeting your Required Electronic Manufacturing Capability, capacity, and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Systems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.