Introduction to electronic packaging

Electronics are often fragile and expensive, it’s critical to know how to pack and ship them safely. Take a look at the guidelines below for properly packaging electronics so you may avoid costly damages and returns when shipping electronic items.

This guideline has been developed to demonstrate packaging best practices that suppliers are expected to adopt in order to best position themselves to provide defect free parts, maximize production efficiency and ensure safety while minimizing overall packaging and transportation costs to meet each customer plants logistics and operational requirements

This is the second post in the series of article on ” Supplier Packing Standards”

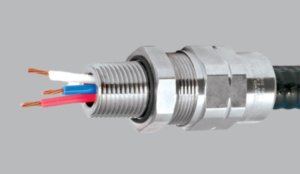

Plastic Components (visually critical) Packaging

For plastic components that are visually critical, design must have the following characteristics:

- Standard container with cover lid

- Inserts with Evolon textile pockets, foam grid or Alveo separators.

- When expendable: inside of the plastic bag for protection and easy repack.

- When expendable: the content must fit to the internal dimensions of any containers whether European or American.

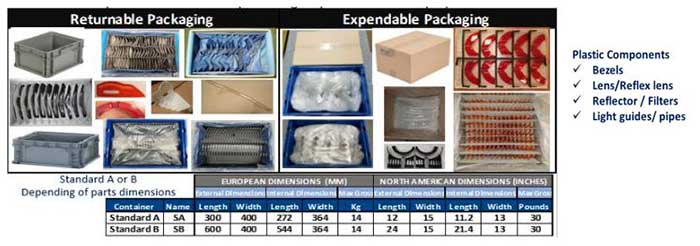

Plastic Components (non-visually critical) Packaging

For plastic components that are not visually critical, design must have the following characteristics:

- Standard container with cover lid

- If needed: a plastic separator can be include.

- When expendable: inside of the plastic bag for protection and easy repack.

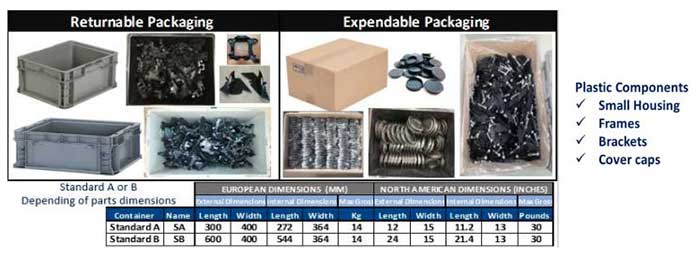

Metallized plastic Components Packaging

For plastic metallized components that are sensitive and visually critical, design must have the following characteristics:

- Standard container with cover lid

- Inserts with Evolon textile pockets, or thermoformed trays.

- When expendable: inside of the plastic bag for protection and easy repack.

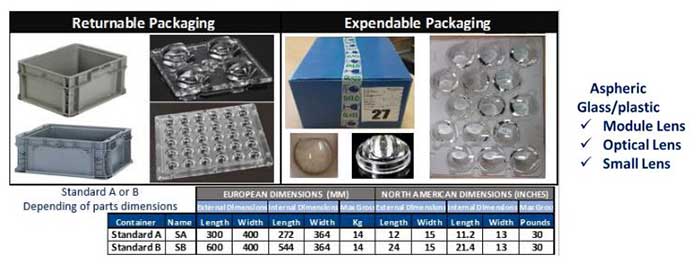

Molded Aspheric Glass/Plastic Components Packaging

For molded aspheric glass/plastic components, very sensitive, design must have the following characteristics:

- Standard container with cover lid

- Thermoformed trays totally covered or Alveo (plastic) separator.

- When expendable: corrugated plastic box to avoid repack.

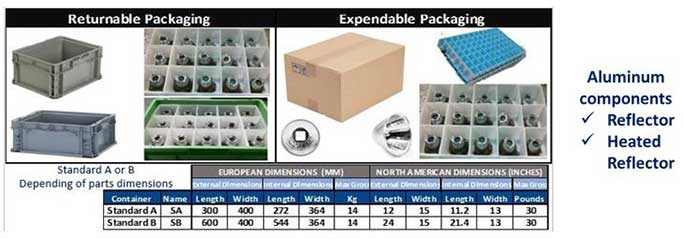

Aluminum Parts (visually critical) Packaging

For aluminum parts that are considered visually critical, design must have the following characteristics:

- Standard container with cover lid.

- Corrugated plastic inserts or Alveo separators.

- When expendable: inside of the plastic bag for protection and easy repack.

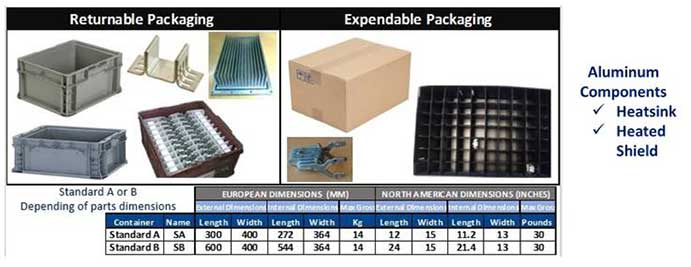

Aluminum Parts (non-visually) Critical Packaging

For aluminum parts that are not visually critical, design must have the following characteristics:

- Standard container with cover lid.

- Corrugated plastic inserts or separators. (bulk, if there is no functional impact)

- When expendable: inside of the plastic bag for protection and easy repack.

Small Parts Packaging

For small parts such as screws and other small components, design of the cartons are standards. However, should have following characteristics:

- Shipped in small lots to fit in small plastics containers.

- Small PE bag per lot of 250, 500 or 1000 pieces according to piece dimensions.

- When returnable: container A with cover lid.

- When expendable: standard carton no more than 9 kg.

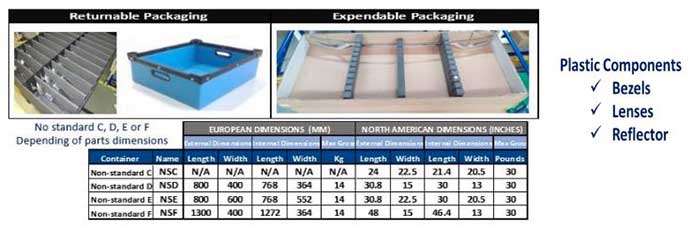

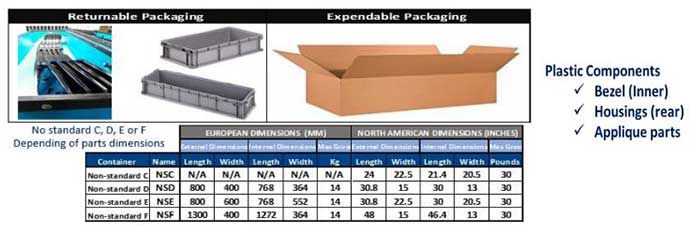

Plastic Components (visually critical) NS Packaging

For visually critical components that dimensions do not fit in a standard size container, an out of the standard container must be used. Design should follow the following characteristics:

- Non-standard container C,D, E or F (returnable) with cover lids

- Inserts with Evolon textile pockets, foam grid or Alveo separators

- When expendable: inside of the plastic bag for protection and easy repack.

- Proposal developed according to the size of the piece.

Plastic Components (non-visually critical) NS Packaging

For components that dimensions do not fit in a standard size container, and pieces are not visually critical, an out of the standard container must be used. Design should follow the following characteristics:

- Non-standard container C, D, E or F (returnable)

- Corrugated plastic inserts. (bulk nested if there is no functional impact)

- When expendable: inside of the plastic bag for protection and easy repack.

- Proposal developed according to the size of the piece.

To know more please read the next part of the series ” Supplier Packing Standards”

EMSxchange Enables you to find a manufacturer meeting your Required Manufacturing Capability, capacity, Certification Criteria from a global electronic manufacturing supplier base. Our manufacturing engineering and supply chain management ensure that all the manufacturing suppliers who register on Manufacturing platforms are Reviewed, evaluated, and audited as per their published capability and performance matrix. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.