Cable Glands

EMSXchange is a specialist in ATEX, IEC Ex (Ex d, Ex e, Ex i, Ex op), Flameproof and Explosion proof cable glands for hazards areas, Oil & Gas, Process and manufacturing Industries

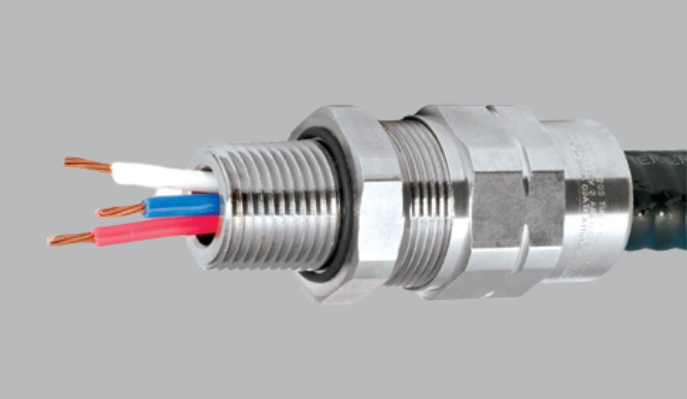

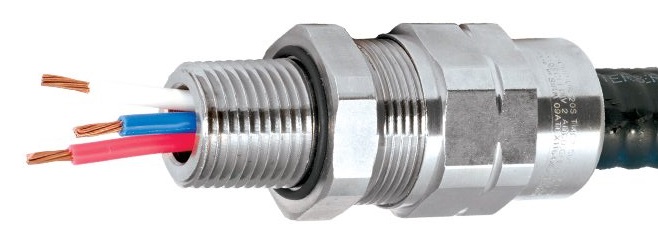

Cable glands are used as a sealing and termination device to ensure that the characteristics of the enclosure which the cable enters can be maintained adequately.

Cable glands are used in all types of electrical power, control, and Instrumentation data and telecommunications cables. Cable glands are suitable for SWA, AWA, STA and Wire Braided cables.

Single compression cable glands and double compression cable glands with accessories (lock nut, IP washer, PVC Shroud).

Armored cable glands are certified for use in ATEX Hazardous Areas

Cable Glands with Ex d/Ex e Zone 1, Zone 2, Zone 21 and Zone 22 approvals for use in Gas Group IIC environments under CENELEC and IEC area classification rules. A

Cable Connectors for NEC and CEC classified Explosive Atmosphere locations, are available for Class I, II and III, Divisions 1 and 2, where Gas Groups A, B, C, D and Dust Groups E, F and G are present.

ATEX, IECEx, INMETRO, CSA, UL, NEPSI, CIDET, CCOE/PESO Approvals. Marine Classification Society Approvals from Lloyds, DNV and ABS

ATEX Cable Glands

Cable Gland Specifications

- Available in Nickel Plated Brass, Brass, Stainless Steel & Aluminum.

- IP66, IP67 and IP68 Compliant.

- EMC Tested.

- Operating temperature -60 to +130°C or -20 to +200°C

- Environmental seal on cable outer sheath.

- Provides a Flameproof seal on the cable inner bedding.

- Provides mechanical cable retention & electrical continuity via armour wire termination.

- Reversible armour cone & Anyway universal clamping ring arrangement allows the cable to be easily disconnected from the equipment.

- Deluge protected as standard.

- Uniform hexagon profile.

The risk of damage to the cable inner sheath is eliminated, regardless of the cable construction, even though the CDS sealing system is fully tightened every time.

Stopper Plugs or Blind Plugs

EMSXchange is a specialist in ATEX, IEC Ex (Ex d, Ex e, Ex i, Ex op), Flameproof and Explosion proof stopper plugs or blind plugs for hazards areas, Oil & Gas, Process and manufacturing Industries

The stopper plugs provide a means of blanking unused cable entries on a temporary or permanent basis. The stopper plugs are available with equipment interface ‘O’ ring seal.

Globally marked to IECEx, ATEX range of stopper plugs are available to suit a wide range of situations.

Stopper Plugs with metric threads made of polyamide and NPT thread in the materials brass and galvanized steel.

Stopper plug is designed for use from the outside of the enclosure to permanently or temporarily close any unused entries. it used to hide any unused entry in electrical equipment.

It is manufactured with a Hexagonal Head, to install or remove in open ended or ring type spanner.

Flame proof stopper Plug

Stopper Plug

Flame proof Bling plug

Types of Stopper Plugs or Blind Plugs

Tamperproof Plug Type CF

Tamperproof Plugs are inserted from the outside with the Allen key towards the enclosure and then tightened from the inside to leave a flush finish to prevent unauthorized removal.

RX Plug Type CB

RX Plugs are inserted with the Allen key pointing away from the box and tightened from the outside.

Hexagon Head Plug Type CK

Hexagon Headed Plugs are inserted from the outside and fastened by means of a spanner. They can be fitted with a washer to increase the IP rating of the assembly.

Dome Head Plug Type CQ

offered as an alternative to the Hexagon Headed version.

Hollow Hexagon Head Plug Type CY

A hollow version of the Hexagon Head Plug.

Specification of Stopper Plugs or Blind Plugs

Materials

Brass: BS2874: 1985 CZ121

Mild Steel: BS970 PT3 230M07

Stainless Steel: BS970 PT3 316 S11

Aluminum: BS1474/1 6082 T4 or T6

Aluminum Bronze: BS1400 1985 AB2 or BS2874:1986 CA104

Thread

Isometric (ISO) to BS3643:1981 and ISO 965 Pts 1 & 3

Imperial (ET) to BS31:1940 (1979)

National Pipe Thread (NPT) to ANSI/ASME:1983

British Standard Pipe (BSP) to BS21:1985

Pg Thread DIN 40430:1971Plating

Nickel, Electro Zinc, Zinc Passivated, chromicized, Electroless Nickel and Anodized.

EMSxchange Enables you to select a Printed Circuit Board , PCB Assembly, cable & wire harness assembly and box build suppliers meeting your Required Electronic Manufacturing Capability, capacity and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.

CerraSystems inc – HDI PCB, Rigid Flex PCB, RF PCB