Conformal Coating Process

1.CLEANING:

- Clean the PCBA’s both the sides with solvent to remove all foreign particles from the board, dip for 3 mins in a poured solvent in the tray, brush clean, and followed by air clean.

- follow general cleaning procedure for cleaning process.

- Surface must be free from dirt, wax, grease, and similar contaminants for successful application of coating.

2. PRE-BAKING

- Bake the PCBA as per the specification of 80 deg C @ 30 mins)

3. MASKING:

- Top & Bottom side masking is required as per customer Requirement.

- Ensure the coating material should be avoid penetrating the connector housing through / even after mask.

- Masking material : Kapton tape/masking tape/Dot labels

- Inspect completely once before taking conformal coating apply at PCBA’s.

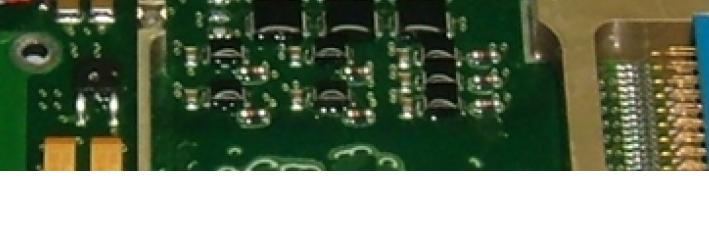

4. CONFORMAL COATING:

- Mix the Material ( For example humiseal-1B73 raw material and 73 thinner 1:1.5 ratio )

- Place the masked (Baked & Cleaned) PCBA on the table horizontally.

- Start spraying from the distance of 12-15 inches away from the board making sure the spray is not directed to one position instead move the can while spraying from left to right and right to left ensuring light even coats.

- Apply the coating material on the board first at bot side by spray method, ensure the thickness should be meet 20um to 40um.

- Cure 5 to 10 minutes in the room temperature if thickness not met in the initial spray, after curing spray additional coats to meet the thickness requirements.

- Make sure the coating uniformity with all the areas in overall board.

- Follow same process to apply the coating material on the board, second sided at top side by spray method, ensure the thickness should be meet 20um to 40um.

- Cure 5 mins in the room temperature if thickness not met in the initial spray, after curing spray additional coats to meet the thickness requirements.

- Make sure the coating uniformity with all the areas in overall board.

5. THICKNESS MEASUREMENT:

A Wet film thickness of conformal coating material 0.8 to 1.5 mils (20 to 40 microns) is to be maintained across the PCBA both bot & top sides.

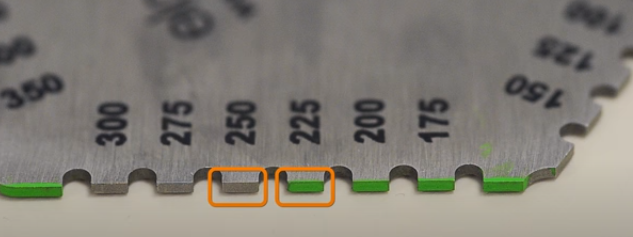

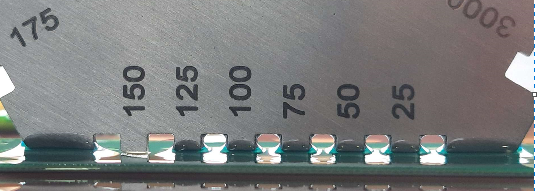

Before leaving assemblies for curing, verify coating thickness in wet condition using wet film comb gauge and tabulate the pre-curing coating measured values for each assembly. Refer below on how to verify the thickness

the first teeth in the comb which is having coating material is 225 so the coating thickness is between 250 to 225 microns, hence wet film thickness is 25 microns.

In the below example, the wet film thickness is reading 25 microns (Difference between 125-150)

Based on the Solids to Liquids ratio which is called as “Volume Solid” whose value is 50% and hence after evaporation/curing the wet thickness will reduce to 50% hence post curing the final thickness will be average 12 to 13 microns.

Based on this study the operator must ensure to coat in 1:2 ratio to achieve desired thickness,

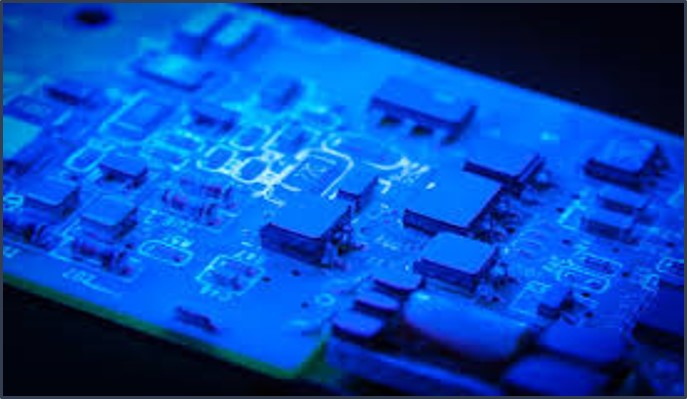

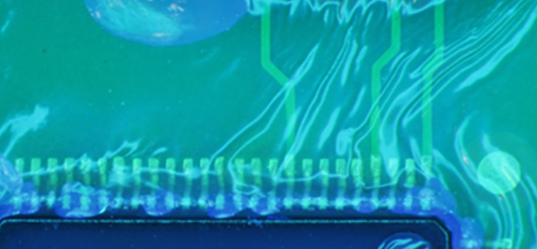

Check for the 100% coverage of coating using UV illuminated magnifier, verify for defects like before leaving assembly for drying.

6. COATING REWORK:

In any condition if conformal coated must undergo any rework/touch up/part replacement Etc., then coating at that location to be carefully removed using specific solvent which can remove acrylic coating prior to rework.

Inspect under UV light illuminated magnifier to check whether conformal coating has been successfully removed to allow soldering for good wetting.

7. POST-BAKING:

Bake the PCBA as per the specification of 80 deg C @ 30 mins)

8. UV TOUCH-UP:

After baking, remove all masking tapes on the board and then touch up wherever irregularities wrt coverage if found through coating by brush and reinspect those locations under UV illumination.

9. FINAL INSPECTION:

Follow conformal coating inspection template to clear boards for next stage.

COMMON COATING RELATED DEFECTS:

- De-wetting:

Caused by contamination on the substrate that is incompatible with the coating (e.g. flux residues, process oils, mold release, and fingerprint oils). Cleaning the substrate thoroughly prior to coating application will generally fix this problem

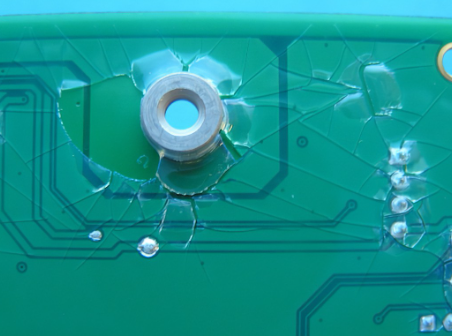

2. Delamination:

An area of the coating loses adhesion to the substrate and can lift from the surface. Like dewetting, it is most often caused by a contaminated surface.

Proper cleaning can take care of this issue. Another cause is insufficient tack time between coats. The solvent has not had the proper time to flash off prior to the next coat.

3. Air Bubbles:

Caused by non-uniform spraying interval or irregular brushing allowing air to trap when there is insufficient tack time between coats.

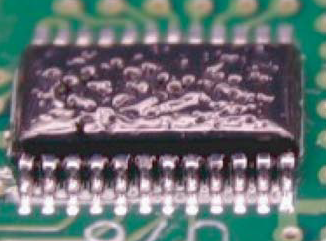

4. Cracking

Excessively high cure-temperature can develop if coating-cure is too quickly implemented. The outer surface of the coating may cure prematurely in relation to its underlying layers, without providing sufficient time for room temperature (RT) drying, a condition that can generate a cracked surface.

When dry, overly thick coating triggers a mismatch with the film’s coefficient of thermal expansion (CTE), another failure mechanism that leads to cracked surfaces.

Performance conditions developing because the PCB’s operating temperature is too high or too low in relation to the film’s acceptable range may generate environmental extremes that interfere with coating flexibility, causing the conformal coating to fracture.

5. Orange peel

The problem of orange peel appearance is almost exclusively found with the use of solvent borne conformal coatings including acrylics, urethanes, and synthetic rubbers.

This is because it is an effect resulting from uneven drying at the surface of the coating

6. Ripples

Cracking and ripples can compromise a conformal coating film, exposing a substrate or PCBA to potential contaminants.

Common causes for cracks and ripples include:

- Coating that is too thick

- Thermal shock

- Coating that has been cured too quickly

EMSxchange Enables you to select a Printed Circuit Board assembly, cable & wire harness assembly and box build suppliers meeting your Required PCBA Manufacturing Capability, capacity and Certification Criteria from a global PCB Assembly manufacturer base.

EMSXchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.