Press-fit Assembly in PCB

A press-fit connection works on the premise of pressing a contact terminal into a printed circuit board (PCB). Press-fit pins are divided into two types: solid pins with a solid press-in zone and compliant pins with an elastic press-in zone.

The telecommunications business was the first to use press-fit technology, which was later adopted by the Automotive industry. Press-fit products and the press-fit termination technology are used by a wide range of customers in a wide range of convenience, assistance, and safety applications, indicating the high acceptance of press-fit products and the press-fit termination technology.

Press-fit Technology

In fact, press-fit solutions are compliant pins with an elastic nature that will flex during insertion and maintain a permanent contact normal force once placed, allowing for a long-lasting electrical and mechanical connection.

Furthermore, when the pin is inserted, strong contact normal forces between the compliant pin and the plated through hole generate cold welded interconnections on their own; especially if tin plating is utilised for at least one of the contact partners (pin/hole). Intermetallic connections are formed as a result of these cold welding procedures, resulting in extremely low contact resistance values. In addition, the mechanical stability is much enhanced.

In general, Press-fit products can be divided into two categories: press-fit contact terminals (for single pin insertion) and connector modules (for mass termination).Customers can put the contacts on their PCBs in a “free” and extremely flexible manner because the press-fit terminals for single pin insertion are frequently supplied in a reeled condition.

Connector modules frequently include highly customizable housing components with contacts (and other sub-components) that can be configured in a modular fashion to meet the needs of individual customers.

Application of press-fit solutions

With the advancement of electronics, intelligent bus systems have begun to take the role of basic cable connections, and intelligent distribution boxes have begun to take the place of simple ignitions.

Safety, performance, and comfort will all benefit from integrated information systems and automated motor control management. The number of electrical connections in automobiles is steadily rising as more electronics are added.

Simultaneously, automobiles are becoming smaller, safer, less expensive, and better. The majority of new applications are controlled by an electrical control unit (ECU), which must be as small as feasible. Each ECU has a PCB that houses the electrical components and follows the same downsizing trend.

More electrical interconnections are required as a result of electronification and shrinking on the same or even less packing space. Miniaturized connector components are being developed as a result of this.

Electrical interconnections, particularly press-fit contacts, are becoming more reliable as the demands of harsher external conditions and increased functional performance increase. Furthermore, as the number of electrical interconnections grows, the demands on each individual component grow as long-term functionality is required for increased quality and reliability.

While the most prevalent PCB thickness in automotive applications is now 1.6mm, future applications may see PCB thicknesses of 1.2mm, 1.0mm, or 0.8mm. This trend, as well as more stringent requirements, must be accommodated by the press-fit solution.

The press-fit technique has a number of advantages that align well with market trends, and it has the ability to be employed in any contact-to-PCB connectivity.

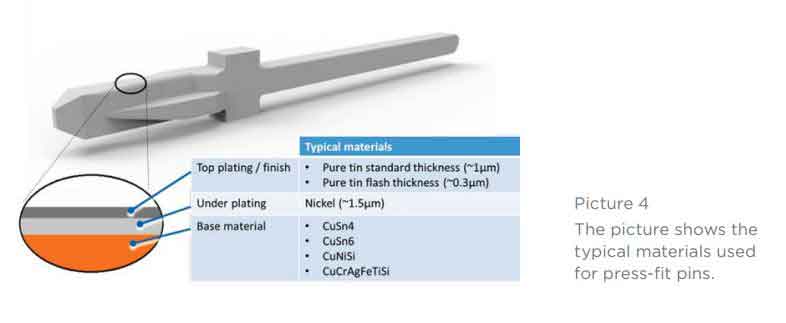

Materials

The sandwich structure of the press-fit pin can be composed of a variety of base materials with two galvanic layers, the under-plating and the top plating. The most prevalent materials and layers used in the automotive sector are shown in Picture 4.

Comparison Press-fit vs Soldering

The changeover to lead-free soldering necessitates an increase in average soldering temperature. Special and more expensive plastic materials, such as LCP, PPS, PPA, and PCT, are required to cope with the higher temperature. By adopting press-fit technology instead of soldering, this disadvantage can be overcome.

For a lead-free application, no expensive high-temperature polymers are required. Whenever space is a consideration for the given applications, press-fit technology offers a solution that would be impossible to achieve with a traditional soldering procedure.In combination with a reflow soldering process, press-fit technology, in particular, offers a solution for large connectors.

SMT reflow is frequently disrupted by large soldering headers. The temperature of the header pins and nearby components is too low, resulting in a faulty soldering operation. This can be rectified by using press-fit technology to add the header after the soldering process. The press-fit pin insertion procedure is a quick, low-cost, and dependable manufacturing method that permits the press-fit pin to be repaired up to two times.

In post-soldering insertion, there are no shading-off concerns with large header components. Also Soldering flaws such as bridges, poor wetting, flux residuals, solder balls, and spider webs are avoided.

Reliability is another crucial component of press-fit technique. One of the most dependable connection procedures is the press-fit connection. The press-fit connection has a fit-rate of 0.005 which is at least 10 times more reliable than soldering or IDC connections, according to the IEC1709 standard.

Of course, to manufacture press fit technology-related modules, you’ll need the right application equipment (instead of soldering equipment). The mechanical equipment can be utilised for a variety of products and applications because it is often very adaptable and automated.

Press-fit Assembly Process

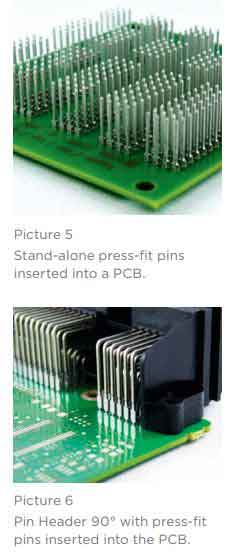

The most basic means of using press-fit technology is a stand-alone pin. Individual pins are placed into the PCB at a high frequency, in most cases using mechanised equipment. The shoulder design of the contact terminal provides the necessary support for pressing the pin into the PCB.

An insertion machine can achieve insertion speeds of up to 5 pins per second for stand-alone pins with a 5 mm pitch. To achieve an optimal connection and assist quality control measures, the insertion process can be managed by measuring press-in force and/or depth.

In most cases, a shroud is used to guide the counter connector afterward. A press-fit pin header, which consists of a plastic housing and contact terminals, is one of the most typical applications. Stitching or an over-molding procedure are usually used to put these pins together.

The pin header’s mating direction to the printed circuit board might be parallel (90°), angled, or perpendicular (0°). The pin header assembly is done with a manual, semi-automated, or automatic connector seating equipment, depending on the annual numbers required. By pressing on the shoulders of the press-fit pins, the pin header is attached to the PCB. There are additional cases where the mounting is accomplished by pressing the pin header’s plastic substance.

An integrated housing or module is another application that is extremely prevalent with press-fit technology. Coils, capacitors, actuators, and sensors are just a few of the components that can be combined in a single enclosure and shared on a single PCB. ABS/ESC housings, sensor housings, and antitheft antennae are all examples of applications that use press-fit technology to make the assembly process easier and more dependable.

EMSxchange Enables you to select a Printed Circuit Board assembly suppliers meeting your Required PCBA Manufacturing Capability, capacity and Certification Criteria from a global PCB Assembly manufacturer base. EMSXchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.