Copper Foil Treatment Process for Printed Circuit Board in India

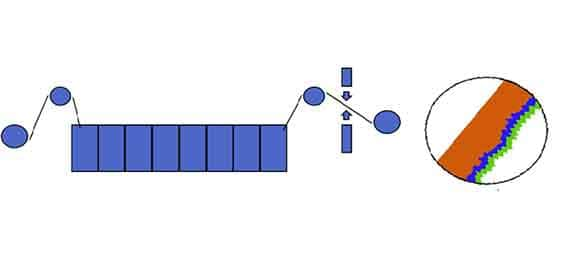

The treatment process converts “drum” foil to foil now suitable for lamination and PCB processing

Copper Foil Definitions

- DSTF (Drum Side Treated Foil) − Adhesion treatment is applied to the shiny/drum side

- RTF (Reverse Treated Foil) − Same as DSTF

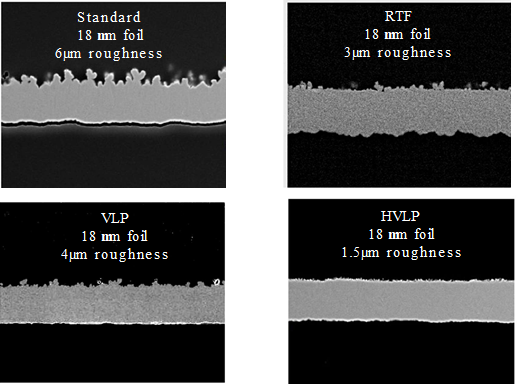

- LP − Low profile foil with tooth 5.1-9.9 microns

- VLP-X − Very low profile foil with tooth < 5 microns

- e-VLP/HVLP − Ultra low-profile foils

LP, VLP-X, and e-VLP-X are applications for:

- Telecom Communication, Mobile MLB

- Storage, switch

- 5G mobile

- 77GHZ Radar

- IoT

- STD HTE (Standard Shiny Copper) − Adhesion treatment is applied to the matte side

STD HTE application for:

- Automotive

- Industrial

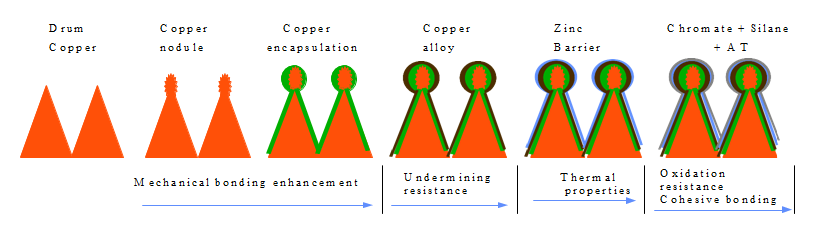

Copper Foil Treatments

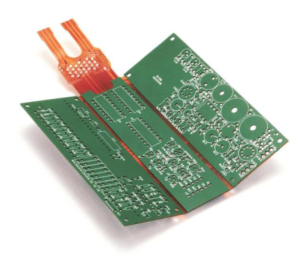

RTF / DSTFoil comparison to standard copper foil

Reverse Treated Foil (RTF):

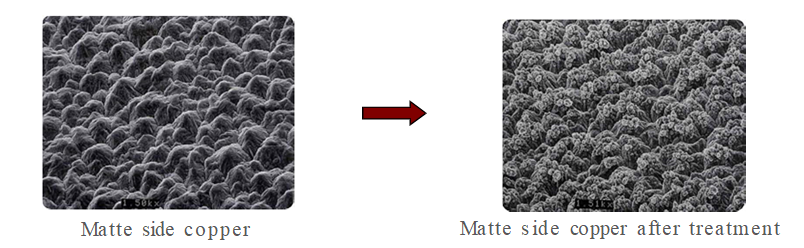

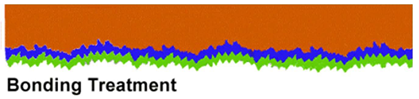

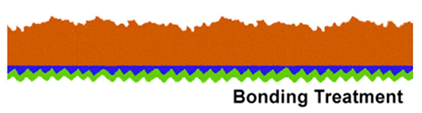

The smooth surface of electrodeposited copper is treated in reverse-treated foils. Treatment layers are thin coatings that improve the base foil’s adherence to dielectrics and add corrosion resistance while roughening the glossy side. The treated side of the copper is laminated to the dielectric material while producing printed circuit board (PCB) panels. The fact that one side of the treated drum is rougher than the other means that it adheres to the dielectric better. This is the most significant advantage over ordinary ED copper. Before applying photoresist to the matte side, no mechanical or chemical treatment is required. It’s already tough enough to hold a good laminate resist.

Copper Foil Surface Profile

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly, and box-build suppliers meeting your Required Electronic Manufacturing Capability, capacity, and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Systems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.