Terminal Box

EMSxchange is a specialist in ATEX, IEC Ex (Ex d, Ex e, Ex i, Ex op), Flameproof and Explosion proof Terminal Boxes for hazards areas, Oil & Gas, Process and manufacturing Industries

Terminal box comes with suitable ingress protection and wide ambient temperature ranges.

A large selection of terminal and cable gland types and accessories enable any build according to user specification with optimal fit to any application requirements.

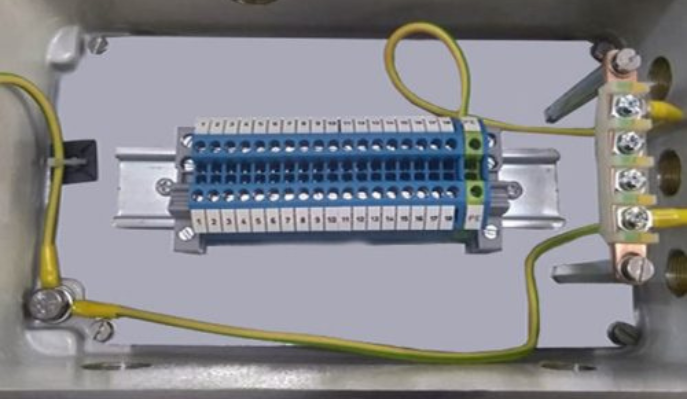

Terminal blocks are used to secure and/or terminate wires and, in their simplest form, consist of several individual terminals arranged in a long strip. Terminals are useful for connecting wiring to a ground or, in the case of electrical power, for connecting electrical switches and outlets to the mains.

Another terminal type are terminal blocks with screws for holding an inserted cable on one end and a plug on the other end so that the block can be inserted into a female connector (this allows for hot-swapping)

Terminal Box is delivered with Testing Report, QC Report, ATEX, IEC Ex (Ex d, Ex e, Ex i, Ex op) and COC certifications with standard warranty

Their distinctive construction features facilitate easy installation and maintenance.

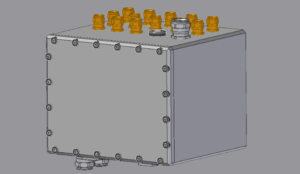

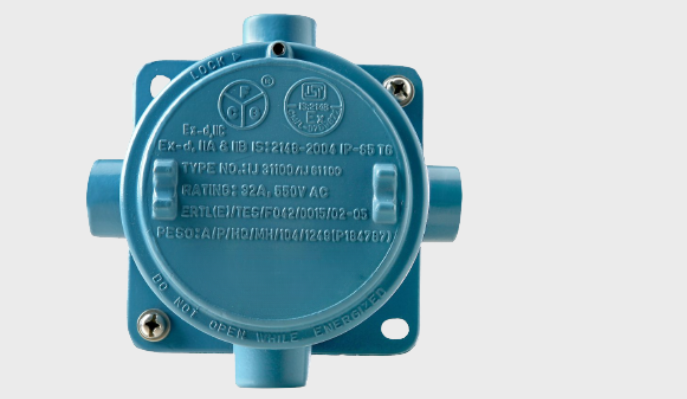

Flame proof Terminal Box

Terminal Box

Terminal Box Configurations

Terminal blocks for “e” increased safety protection in Ex Zone 1 and 2 or 21 and 22

When the installation instructions are followed, the terminal blocks satisfy the requirements for “e” increased safety protection. The terminal blocks are therefore approved for installation in Zone 2 and, in particular, Zone 1, i.e., in the actual Ex area.

Zone 21 and Zone 22, however, is only on condition that the terminal blocks are installed in connection boxes. The connection boxes must also be approved for “e” protection and must have at least IP54 protection.

Terminal blocks for “i” intrinsic safety protection in Ex Zone 0, 1, and 2 or 20, 21, and 22

No special approval is required for terminal blocks in applications with “i” intrinsic safety protection.

In addition to Ex e approved terminal blocks, standard terminal blocks can also be used here, taking IEC/EN 60079-11 into consideration.

Ex e and Ex i terminal blocks in the same housing

In equipment, such as Terminal boxes, both intrinsically safe circuits (Ex i) and increased safety circuits (Ex e) can be combined. Safe mechanical isolation and, if necessary, visual separation are prescribed here. It must be ensured that individual conductors do not come into contact with conductive parts of the other circuits when the wiring is disconnected from the terminal block.

Junction Box

EMSXchange is a specialist in ATEX, IEC Ex (Ex d, Ex e, Ex i, Ex op), Flameproof and Explosion proof Junction Boxes for hazards areas, Oil & Gas, Process and manufacturing Industries

Junction boxes can come in many different sizes depending on the number and type of connections required. Junction boxes used in industrial applications are often custom built to support many different types of wire and cable entering and exiting the box.

The junction box is mounted to a structural point on either a building or on machinery. Many attributes simplify installation and handling such as dedicated pry points for opening, a foamed gasket and special protection for the sealing edge.

Explosion-proof terminal box is designed for extremely harsh industrial hazardous areas with the features of high anti-corrosion, water-protection and dust-protection to fully meet the requirements by the chemical, petroleum and offshore industries.

The material of explosion-proof Junction box is SS304, SS316L, or carbon steel (powder coated). The standard wall thickness is 1.5mm, also 2mm is available for ordering to make. It could be formed by cover or door. These are applicable for the cable branching, wiring in different electrical apparatus and instruments.

Different type and specification cable glands either made in plastic or metal material apply to different cable entries. The unused entries can be sealed with the stopping plugs which is very convenient for future expansion.

Junction Box is delivered with Testing Report, QC Report, ATEX, IEC Ex ( Ex d, Ex e, Ex i, Ex op ) and COC certifications with standard warranty

Junction Box Specification

- Material: SS304 (wire drawing processed), SS316L (wire drawing processed), Carbon steel (plastic powder coated)

- Can be used in zone 0, zone 1, zone 2, zone 20, zone 21 and zone 22

- Anti-Corrosive Epoxy Powder Coated (631 Shade of IS5) Finish

- M6 Earthing

Flame Proof Junction Box

ATEX Junction Box

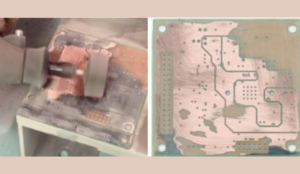

EMSxchange Enables you to select a Printed Circuit Board , PCB Assembly, cable & wire harness assembly and box build suppliers meeting your Required Electronic Manufacturing Capability, capacity and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.

CerraSystems inc – HDI PCB, Rigid Flex PCB, RF PCB