There are many methods used to remove the conformal coating from a Printed Circuit Board Assembly (PCBA). The most common methods are mechanical abrasion, chemical abrasion, and thermal stripping.

Mechanical abrasion involves using abrasive materials such as sandpaper to physically remove the conformal coating from the board. This method is often used when a board has a large area of conformal coating that needs to be removed.

Chemical abrasion is a process that uses solvents to dissolve the conformal coating from the board. This method works best for small areas of conformal coating that need to be removed.

Thermal stripping is a process that uses heat to melt the conformal coating from the board. This method is best for more delicate boards and components as it does not damage the board or components

Why is Conformal Coating Removed?

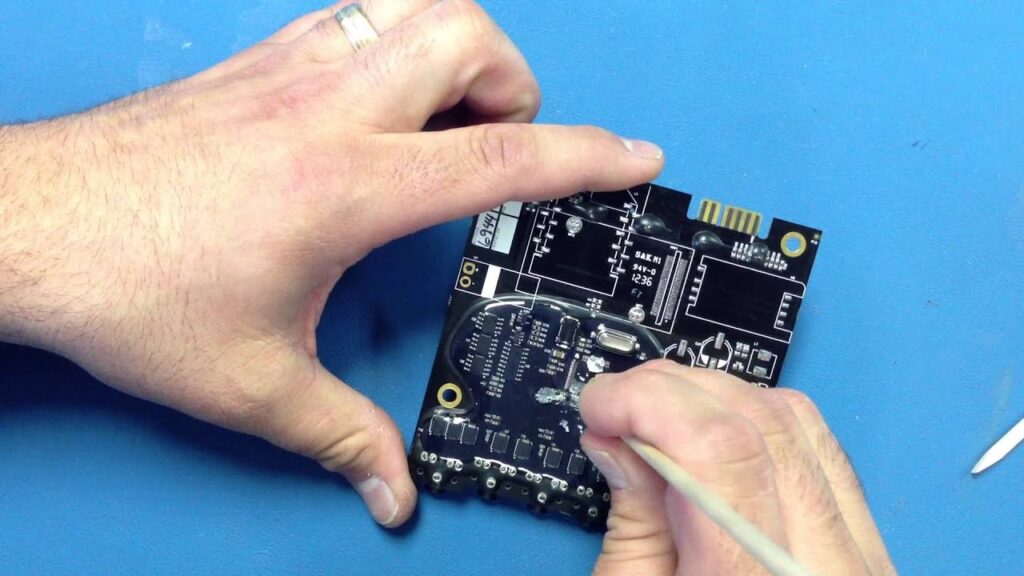

Conformal coating can be removed for a variety of reasons. It may need to be removed in order to gain access to components underneath the coating, to allow for repairs or modifications, or to replace components. It may also need to be removed to inspect for possible defects or contamination. In some cases, it may also need to be removed to verify that the coating process was properly done.

One of the most common reasons is to make repairs or modifications to the circuit board. By removing the conformal coating, technicians can easily access the components on the board and make any necessary changes. Additionally, conformal coating can sometimes interfere with the testing of the board, so it may need to be removed in order to ensure proper operation. Finally, the conformal coating may need to be removed prior to reworking or cleaning the board.

Types of Conformal Coating

1. Acrylic Conformal Coating: Acrylic conformal coatings are the most commonly used type of conformal coating. They are UV-stable and provide excellent insulation and moisture protection. Acrylic conformal coatings can be applied either manually or by automated machinery.

2. Silicone Conformal Coating: Silicone conformal coatings are ideal for applications where high moisture resistance is required. They are also highly resistant to temperature fluctuations and have excellent dielectric properties.

3. Urethane Conformal Coating: Urethane conformal coatings are extremely durable and provide excellent protection against harsh chemicals and solvents. They are often used in high-temperature applications and are relatively easy to apply.

4. Epoxy Conformal Coating: Epoxy conformal coatings are extremely strong and provide excellent protection from chemicals and solvents. They are usually applied with automated machinery and are most commonly used in industrial environments.

5. Polyurethane Conformal Coating: Polyurethane conformal coatings are highly resilient and offer excellent protection from abrasion and corrosion.

Chemical Solvent Method for Conformal Coating Removal

The chemical solvent method is one of the most popular methods for conformal coating removal. This method involves using a chemical solvent, such as acetone, to dissolve the conformal coating and then wiping it away with a cloth.

This method is often used when the conformal coating is too thick or difficult to remove with mechanical methods. This method is also often used when the conformal coating is on a delicate surface or when the part needs to be reused.

The chemical solvent method is usually the quickest and most cost-effective method for conformal coating removal.

Peeling Method for Conformal Coating Removal

The most common method used to remove the conformal coating is a chemical peel. This method involves applying a chemical agent to the surface of the component, which breaks down the coating and allows it to be peeled away. This method can be used with a variety of different chemicals such as methylene chloride, acetone, and trichloroethylene. The chemicals used for this method must be handled carefully and should be stored in a well-ventilated area.

Thermal Method for Conformal Coating Removal

The thermal method for conformal coating removal is a process that uses heat to melt off the coating from a printed circuit board Assembly (PCBA). This method is used when the coating is difficult to remove using chemical solvents or mechanical abrasion. The thermal method is often used when the coating is made of polyurethane, polyimide, polyamide, silicone, epoxy, and acrylic.

The process is done by using a hot air gun or infrared lamp to heat the coating until it becomes soft and malleable. Once the coating is soft, it can be scraped off with a blade or other tool. This method of removal is relatively safe, but it is important to use safety equipment, such as gloves and eye protection, to avoid any contact with the heated coating.

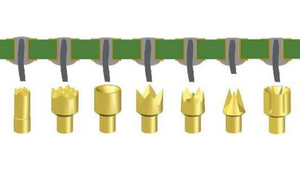

Grinding and Scraping Method for Conformal Coating Removal

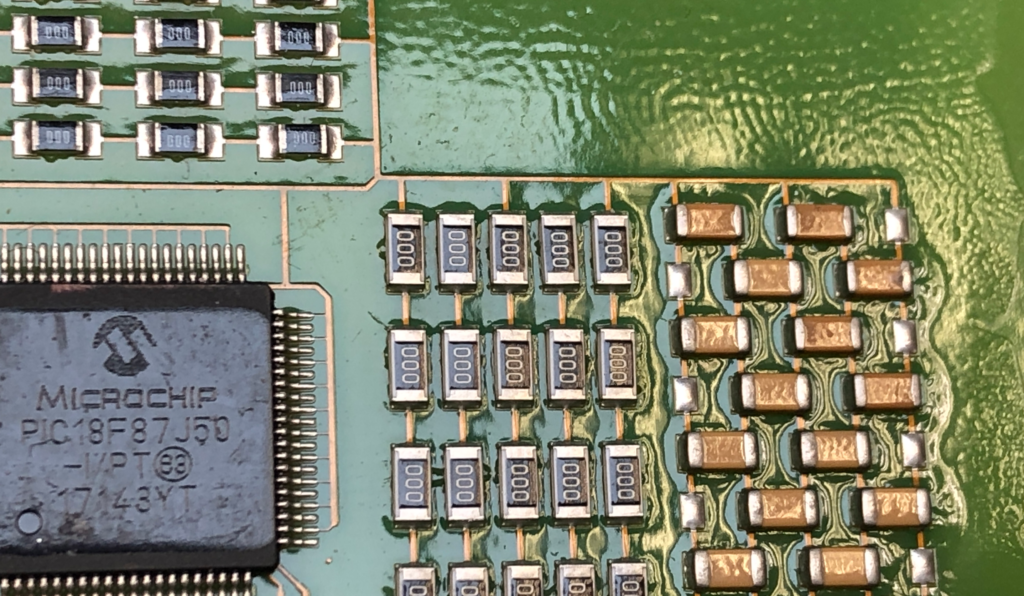

Conformal coating removal is a necessary step in the manufacturing process of many electronic components and devices. The coating is applied to protect the underlying components from moisture and other environmental factors. In order to inspect, repair, or rework the components, the coating must be removed.

Grinding and scraping are two common methods used to remove conformal coatings. Grinding is typically used for removing thick coatings of materials such as epoxy or silicone. In this method, a grinding wheel is used to abrade the surface of the coating, reducing its thickness or removing it entirely. This method is relatively fast and provides good surface coverage. However, it can cause heat damage to delicate components due to the high temperatures generated during grinding.

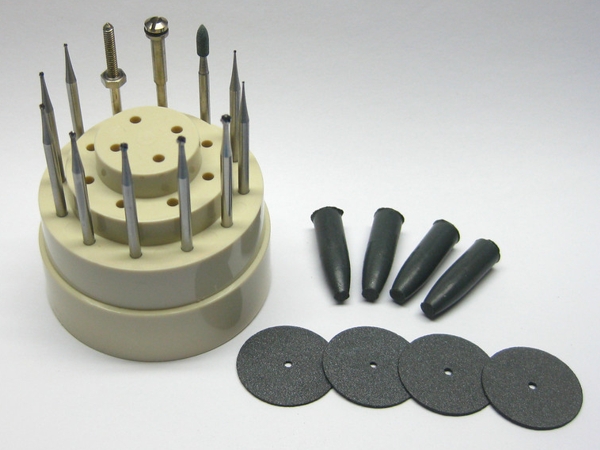

Micro Sandblasting method of conformal coating removal

Removing conformal coating using a micro sandblaster is a process that requires a steady hand and patience. The sandblasting process is used to remove thick layers of conformal coating that may have been applied to protect delicate electronic components from environmental damage.

The Micro Sandblasting process is less aggressive than other methods of removal, such as chemical stripping, and can be used to selectively remove the coating from specific areas.

1. Gather all necessary materials. You will need a micro sandblaster, a respirator, a supply of compressed air, a vacuum cleaner, and an appropriate grit of sand or glass beads.

2. Set up the sandblaster and connect it to the compressed air. Adjust the pressure as necessary for the task.

3. Put on the respirator and place the vacuum cleaner near the sandblasting area to collect the particles from the sandblasting process.

4. Start sandblasting the area where the conformal coating needs to be removed. Keep the nozzle of the sandblaster moving back and forth over the area, sweeping the nozzle in a smooth motion.

5. Continue sandblasting until the conformal coating has been removed.

6. Clean up the sandblasted area with a vacuum cleaner to remove any residual particles.

7. Inspect the area to ensure that all of the conformal coatings have been removed.

8. Disconnect the sandblaster and clean up any residual particles.

Following above steps will ensure that the conformal coating is removed safely and effectively. If you are unsure how to use a sandblaster, it is best to seek professional advice before proceeding.

EMSxchange Enables you to select a Printed Circuit Board , PCB Assembly, cable & wire harness assembly and box build suppliers meeting your Required Electronic Manufacturing Capability, capacity and Certification Criteria from a global Electronic contact manufacturer base.

EMSXchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.

Cerra Systems inc – HDI PCB, Rigid Flex PCB, RF PCB