Box Build Assembly Process

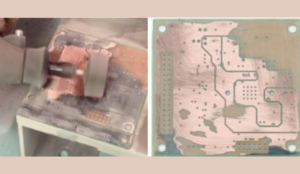

A box build also called as “systems integration” includes all the other assembly work involved in an electromechanical assembly, other than the production of the printed circuit board.

Each project’s box build assembly process is unique, and each step might have varied degrees of difficulty. One approach, for example, could be to simply place a printed circuit board assembly (PCBA) inside an enclosure. The hard process of connecting a PCBA to a user interface display may be the next step. Installation of sub-assemblies, installation of other components, routing of cables or wire harnesses, and fabrication of enclosures are the most frequent box build assembly processes.

What You Need for the Box Build Assembly Process

You must first locate a contract manufacturer who specialises in this capability before having your electronics enclosure—or box—built. Many manufacturers will build a box for you, but you should look for one that has experience building all of the components of your electronic item for the greatest results.

You won’t have to worry about attempting to coordinate your product between numerous vendors if you use a contract manufacturer that can build the full product. Furthermore, having your complete product made by a single vendor ensures that specific components like circuit boards and wire harnesses are designed to operate together.

After you’ve chosen a contract manufacturer for your project, you’ll need to provide the contract manufacturer your instructions for building the box. These should include:

- Bill of materials (BOM)

- Electrical schematic

- Assembly drawing(s)

- Wire list(s)

- Test specification

- An example (golden) unit if available

Your contract manufacturer will most likely be able to construct the box using simply a bill of materials and an electrical schematic, but they may be incomplete. This may result in a flurry of questions from them, as well as numerous meetings to better grasp your requirements. Finally, it is usually preferable to provide them with as much information as possible.

The most important thing is to be ready to collaborate with your contract manufacturer throughout the box-building process. You’ll want to make sure they have all of the information they need to complete your project correctly.

Your Contract Manufacturer’s Process for Box Build Assemblies

Here is the typical process that occurs now that your CM is ready to construct your project. Printed circuit board assemblies (PCBAs), wire harnesses, point-to-point wiring, and the box’s mechanical frame are typically included in a box build. It’s like putting a layered cake together, and the sequence in which all of these elements are put together is crucial to the project’s success. They’re usually completed like this:

- Build and test all of the PCBAs used in the device.

- Build and test all of the device cables and wire harnesses.

- Cut, strip, and label the ends of the individual wires in preparation for their assembly.

- Start the assembly of the box build from the bottom, and work up through each level. This will include bolting parts together, seating and interconnecting circuit boards, and connecting all of the wire harnesses and point to point wiring.

- Incorporate customer manufacturing and workman specifications into each level of the assembly.

- Inspect each level of the assembly for required labels, wire routing, screws with critical torque specifications, and continuity test points. This becomes especially important for areas of the product that will not be accessible after the next level of assembly.

- Continue through each level, or layer, of the assembly.

- Conduct a final inspection prior to installing the covers of the assembly.

- Test the device and record the results.

Although some simple box builds may pass their final test with a simple PASS/FAIL, a good contract manufacturer would usually gather more information. They’ll most likely work with the test fixture and specs you provide to create a more thorough test procedure. Although this requires additional upfront preparation on the part of the contract manufacturer, it usually pays off in the long run by reducing errors and returned goods.

Common Box Build Assembly Services

A list of common box build assembly services provided by an Electronic Manufacturing Services (EMS) provider is as follows:

- system level assembly

- product assembly

- sub-level product assembly

- packaging

- labeling

- testing

- software installation

- product configuration

- warehousing

- order fulfillment

- after-market service

- repair

Providing all of the details involved in a complete product assembly to an electronics contract manufacturer might help them model a box build assembly method that best serves the customer.

5 Things To Consider For Box Build Assembly Process

If you’re thinking about implementing a box build assembly process in the near future, here are some things to consider. By supplying the following information, you may assist the assembly services provider.

- Bill of Materials (BOM): This is a crucial requirement for any provider of Electronic Manufacturing Services. This allows them to obtain a better sense of all the important components, and it is needed to specify the materials that must be sourced by the EMS supplier. It should also specify what will be provided free of charge by you. You must determine whether to identify smaller objects like tie wraps, adhesives, nuts and bolts, heat shrink, washers, and so on. Wires and their IDs are in the same boat. While these are considered consumables, keep in mind that they still have a cost and must be purchased. As a result, they must be defined in order to minimise unanticipated production delays and cost increases.

- Assembly: If at all possible, provide 3D CAD models. This aids in visualising the finished outcome. Free drawing viewers are available in a number of CAD systems. Many advanced EMS providers provide CAD tools that make it simple to convert designs into build instructions, as well as make revisions if necessary. A layout drawing with critical component details should be included.

- Sample Unit: A sample unit is always useful and can be a valuable source of information if the designs are incomplete. In this case, you will undoubtedly require the services of a provider who can design and develop the plans for you in order to ensure reliable construction.

- Dimensions: The size and weight of the unit should always be communicated to the EMS provider. This is necessary not only for transportation but also for handling and storage during the entire construction process. You should also think about and decide how the finished product will be packaged and carried.

- Testing: Basic electrical safety testing, such as earth bond and flash tests, should be specified in the case of electrical systems. Are you willing to undertake some functional testing or factory acceptance testing before shipping a product to a customer? Is a visual examination sufficient? If necessary, get guidance from an EMS provider to answer these questions, as they will have the appropriate knowledge and experience with what works best.

Whether your design requires a simple, uncomplicated box construction assembly or a more complex assembly, supplying accurate data up front is essential. It ensures that you get off to a solid start, with everyone knowing what is expected of them.

EMSxchange Enables you to select a Box Build, Enclosure manufacturers meeting your Required System and sub-assembly Manufacturing Capability, capacity and Certification Criteria from a global Box build and sub-assembly manufacturers base. EMSXchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.