Counterfeit Parts

Counterfeit parts are now the biggest problem in today’s Industrial, Military and space market. Electronic components Market is flooded with counterfeit parts due to the pressures of Obsolescence and in many cases urgent delivery, declining availability and lower cost, parts are being procured from unknown or unproven supply chains to satisfy budget and production requirements.

In fact, even proven supply chains have been duped by previously reliable sources to introducing counterfeit parts into the Market in some cases unknowingly increasing the presence of counterfeit parts in the supply chain.

If Purchasers remain within the 1st and 2nd tier Parts Suppliers including Manufactures, Franchised Distributors and Authorised Parts Agency then the parts supply is in most cases underwritten and guaranteed. If Purchasers or indeed Distributors turn to suppliers outside of this inner circle, then the risk of receiving counterfeit parts is very high.

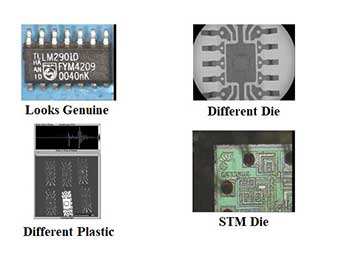

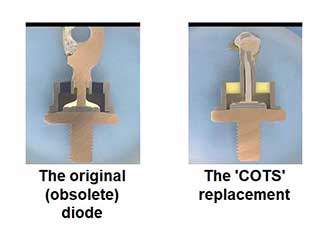

Counterfeit parts come in many forms:

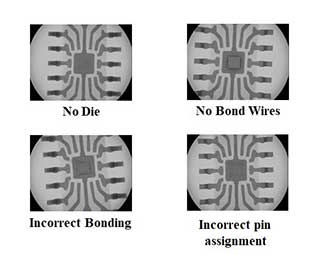

- New productions using cheap or in some cases no die

- Recovery of scrapped parts( these are the real parts but previously found to fail but find there way back into the market) these are the hardest counterfeit parts to identify since they are essentially physically the same as genuine parts.

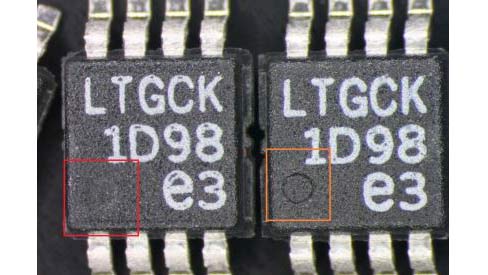

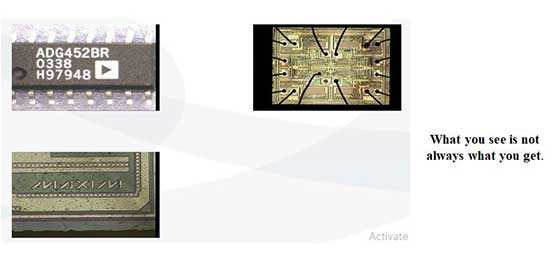

- Remarked parts comes in many forms starting with parts from cheaper sources and marked with higher quality part numbers or simply adding higher quality codes to existing commercial parts

Countering presence of Counterfeit parts

There are several established methods of countering the presence of counterfeit parts which includes both destructive and non-destructive means.

- Supply Chain and Source Controls

- Beware of unreasonably priced offers

- Most legitimate Suppliers will offer sale and return guarantees in the event of failure( though the incidence of Franchised Distributors citing Non-refundable/ Non Cancellable T&C’s are increasing)

- Documentation, Manufacturers CoC( most Suppliers/Manufacturers will accept to verify if a given part number and lot date code exist, though this does not necessarily prove the heritage of the received procurement lot)

- External and mechanical inspection( careful performance of external visual and mechanical dimensions may reveal deviations not previously seen on the manufactured part)

- Parts Package traceability information( comparison with legitimate Manufacturers packaging and packaging is a valuable tool)

- Delivery Documentation other than CoC( Manufacturer Advice notes and Delivery slips can also be inspected against known formats)

- Weight(if sufficient statistical data is available this may be used as a course gauge)

- Solderability(condition of lead solder and the results of solderability may indicate problems)

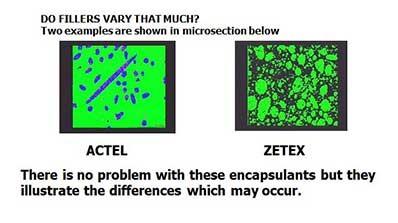

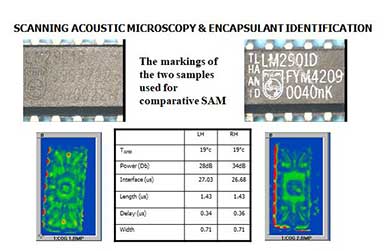

- CSAM( IGG has shown in the case of plastic parts, variations in the package filler and paddle construction pointing to counterfeit packaging)

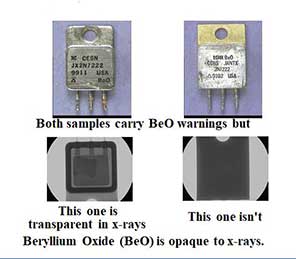

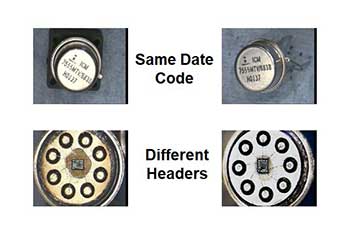

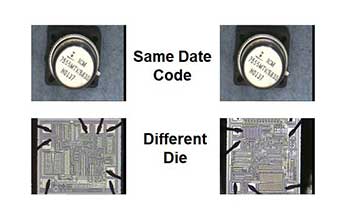

- X-ray( IGG has been able to map the internal construction including bonding and die orientation leading to identification of counterfeit parts)

- Fine&Gross Leak( useful tool to identify parts with substandard assembly leading to identification of counterfeit parts)

- EM-Room( can be used to confirm correct part function but is not 100% effective confirmation since some counterfeits are remarked commercial parts which provide correct functionality at room temperature but fail at temperature extremes)

- RM-Hi-Lo(a very good guide to military temperature range operation and will identify remarked commercial parts)

- Marking Permanence(an efficient method of identifying remarked parts but not conclusive when sophisticated re-marking is used)

- Mechanical Integrity(lead pull and package integrity have also been used to identify substandard assembly)

- PIND(will identify poor assembly but cannot be used to uniquely identify Military parts, remains a useful tool)

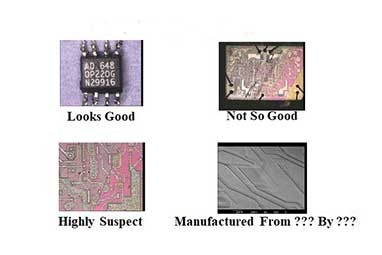

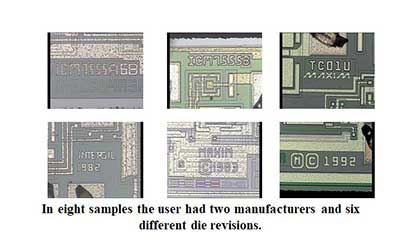

- Decap(can be used to very construction and die topography including importantly die numbers, revisions and lot codes)

- Microsection( can be used to assess design, construction and materials either as an investigative or as a comparative tool)

- Accelerated Tests;HAST, 85/85(these may be used to verify the harsh environment performance and confirm Military part performance).

Manufacturers Typically cooperates with Parts Agencies and Customers in identifying these parts and removing them from the marketplace. Manufacturers are in many cases willing to verify part types against lot/date codes wherever possible (this has previously been difficult, but manufacturers are becoming more aware of the need to participate in the counter programs) But this alone is not sufficient.

Supply Chain Management, procurement & documentation controls the performance of Receiving Inspection followed by Destructive Physical analysis and in some cases comparison with statistical/baseline documentation formats, design, construction, assembly and material data will continue to be the best protection to prevent counterfeit parts entering your production line.

Finally, once a counterfeit is suspected or confirmed inform the Supply Chain, Customer, Manufacturer, raise the national NCR/Alert and confirm final disposition/destruction of parts. Revise Supply Chain Control and Counter Counterfeit Measures accordingly.

Counterfeit parts remain a major concern for the Military & Space Market though the procurement and Purchasing controls employed within the Military and Space Market are currently managing the risk to some extent.

Counterfeit parts will continue to threaten the Military & Space market because of the huge profits which can be made by selling parts up the market to Military & Space level where profits of many thousand times can be made very quickly. Selling a commercial part costing cents as Space Grade can net hundreds if not thousands of dollars a part.

Counterfeit Parts Examples

Lot Homogeneity

Generally Commercial parts do not have any regulation to control lot homogeneity other than the self-regulation and the DSCC VID registration.

This means that commercial parts produced within a single Procurement Lot may not utilise the same design, process and materials.

IGG has experienced receiving different package sources and die sizes within the same procurement lot.

Since any variation in design, process and materials will invalidate previous Evaluation results it is very important to ascertain the lot variance before performing Evaluation or Batch Acceptance Testing.

Clearly it would be useful to contact the manufacturer and determine if any variation or changes have been made. Procurement against a VID specification will help to control this variation.

Procurement against a Datasheet Issue/Rev will not necessarily assure that parts have been manufactured with the same design/process/materials.

There are a number of non-destructive tests which can be performed to identify a baseline condition of the parts and inspect the procurement lot for lot variation.

Once lot variations or homogeneity has been established the proposed Evaluation and Batch Acceptance can be adjusted accordingly.

It is possible to adjust the Evaluation and Batch Acceptance testing to compensate for the identified lot variation and produce an acceptable Procurement Lot.

Constructional Analysis can be used to verify of the design, process and material variations to a degree and establish the baseline for future examinations.

EMSxchange uses a unique, proprietary vendor evaluation & qualification system to onboard vendors. We maintain a close view of their capability, capacity, and compliances. 25+ years of manufacturing experience has given us strong capabilities to understand customer requirements and supplier capabilities. EMSXchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door. EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Sytems (AESPL) – PCBA, Cable Assembly, Box Build.

Cerra Systems inc – PCB Manufacturing.