Automated Test Fixtures Development Process

Testing of electronic assemblies involves three elements: the device under test, test equipment, and fixturing to make the connections between them. The challenge for a test engineer building a sophisticated test system is that instrumentation may need to measure thousands of test points through the mechanical interconnect.

Test Fixture Overview

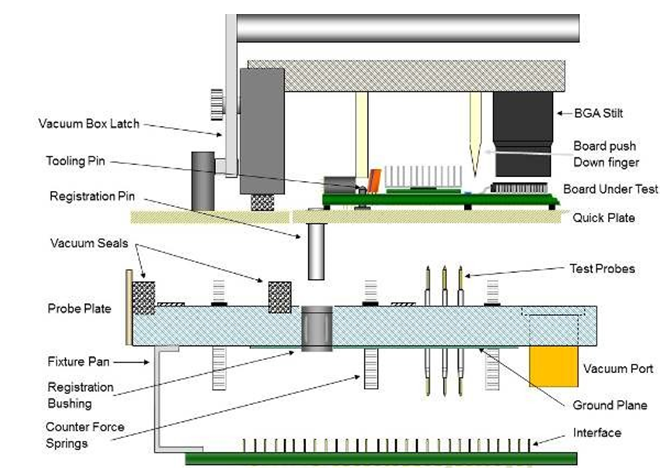

Below is a general representation of an automated test fixture. The vocabulary often used to define fixture-based test systems include:

- Bare-board test – Printed circuit boards which are tested before any components are mounted.

- In-Circuit Test – Electrical test on an assembled board to check that all components are present, of the correct type and value, and connected together as expected with no shorts or opens.

- Functional Test – Testing a printed circuit board or product that is powered up and the circuit is exercised while operating.

Types of Test Fixtures

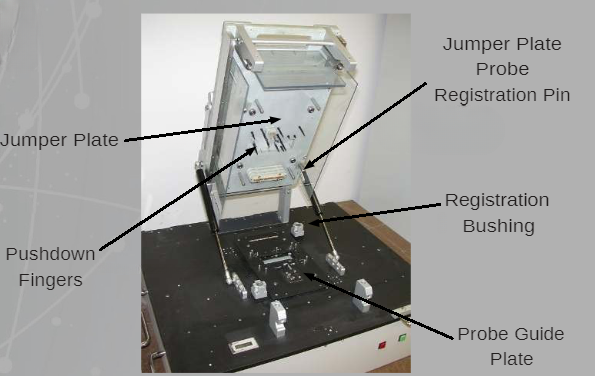

There are several common approaches to applying force to hold a PCB or PCBA against spring test probes, including mechanical arrangements, pneumatics and vacuum systems.

In a mechanical system the probe plate and the product PCB are brought together by mechanical cams, levers and linkages. There are a wide variety of schemes in use, differing in complexity and cost.

In more sophisticated test systems, most of the complexity is ensuring that the planes of the PCB Assembly and the probe plate remain parallel as the fixture operates.

Test Fixtures Drive Types:

- Manual drive Test Fixtures

- Pneumatic drive Test Fixture

- Vacuum drive Fixtures

Manual Drive Fixture:

In simpler systems the pressure plate supporting the hold-down posts simply hinges down over the product.

Manual Drive Fixtures

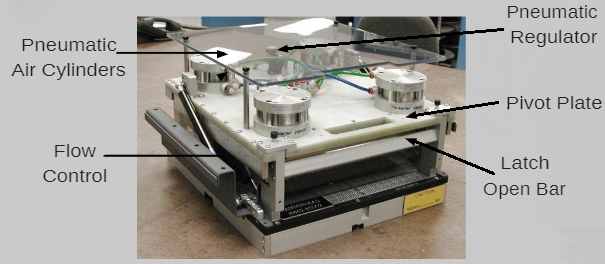

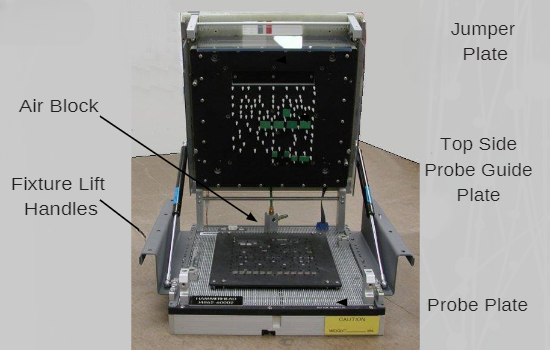

Pneumatic drive Fixture

In a pneumatic system, the area between the probe plate and the product tested is pressed together by pneumatics that are placed on the top or bottom side of the fixture, sometimes both sides.

Pneumatic Drive Fixture

Pneumatic Drive Fixture

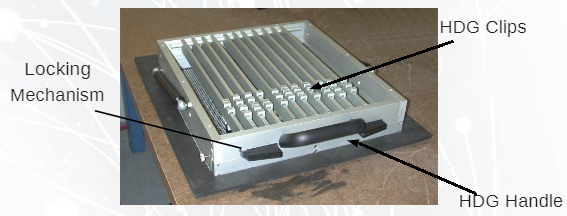

Heavy Duty Gate (HDG) – CAM Fixtures

Heavy Duty Gate (HDG) – CAM Fixtures

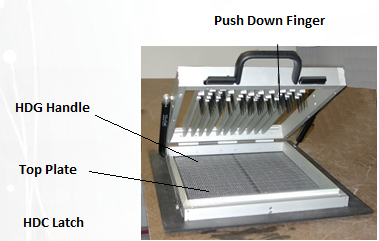

Heavy Duty Gate (HDG) – Thumb Latch Fixtures

Heavy Duty Gate (HDG) – Thumb Latch Fixtures

Heavy Duty Gate (HDG) – Thumb Latch Fixtures

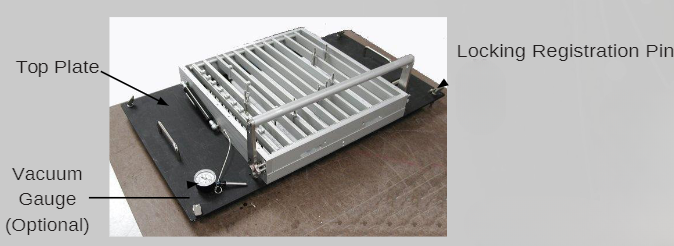

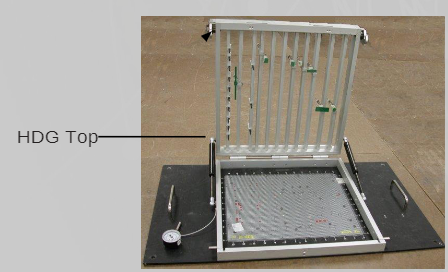

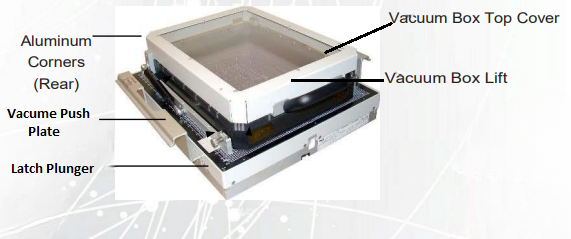

Vacuum drive fixture

The area between the probe plate and the product tested is a sealed cavity. A vacuum applied to this cavity pulls the two together.

Vacuum drive Fixtures – Vacuum Actuation

Vacuum drive Test Fixtures

Vacuum drive Test Fixtures

Test Fixture Wiring

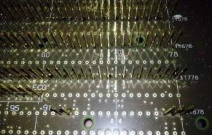

There are multiple methods of establishing contact between the product printed circuit board being tested using a probe-based test fixture, commonly called bead-of-nails fixture. These methods include long-wire, short-wire, and wire-less fixtures.

Selecting the proper fixturing approach for a specific application is important to total system costs and tester longevity. In addition to fixture type, decisions often must be made as to allow for removable fixtures using some form of mass interconnect between the test instruments and the fixture.

Long Wire Fixtures

On lower probe count product PCBs or prototypes where the design is subject to change, long-wire fixtures provide a very economical approach because they avoid nonrecurring costs.

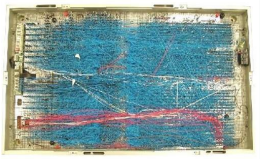

Long Wire Test Fixtures

Short Wire Fixtures

Short-wire fixtures provide better signal fidelity than long-wire fixtures. Changes to a short-wire fixtures are often more difficult to perform than long-wire fixtures due to the wire densities associated with their compact design.

Short Wire Test Fixtures

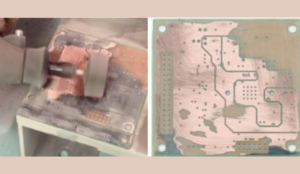

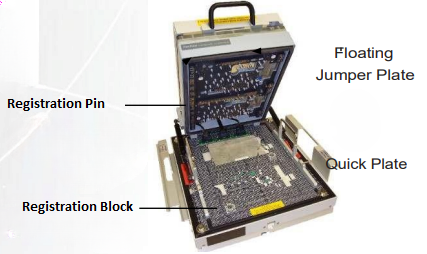

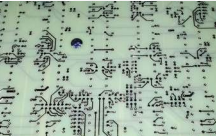

Wire-less Fixtures

Advantages of a wire-less fixture include decreased debug time, greater signal fidelity, increased capabilities to test low voltage and multi-logic modules, and reduced signal crosstalk.

Wire-less fixtures generally perform much more reliably than wired fixtures because PCB designers can control exactly how each trace is routed on the bottom side of the T-board, making it possible to isolate troublesome signals.

Double-Ended probes contact the Gold pads on the topside of T-Board.

Stake Pins are soldered into the T-Board to make contact the tester’s interface

EMSxchange Enables you to select a Printed Circuit Board, PCB Assembly, cable & wire harness assembly and box build suppliers meeting your Required Electronic Manufacturing Capability, capacity and Certification Criteria from a global Electronic contact manufacturer base.

EMSxchange takes complete responsibility and ownership for your electronic manufacturing process and all its deliverables from contract manufacturing supplier selection to manufacturing to quality inspection to shipment and delivery to your door.

EMSxchange Electronic Manufacturing Partners Profile includes:

Argus Systems (AESPL) – PCB, PCBA, Cable Assembly, Box Build, Testing.

CerraSystems Inc – HDI PCB, Rigid Flex PCB, RF PCB